Vantage V8 4.7 engine rebuild

#1

Vantage V8 4.7 engine rebuild

Hello,

I would like to document an engine rebuild I did this summer on a 2009 Aston Martin Vantage V8 4.7. Engine was seized due to oil starvation and spun main bearings. Even with all bolts loose on the main bearing girdle and me hanging on a 3 foot breaker bar off the crank pulley it would not turn.

I called Lake Forest Sports Cars in Lake Forest, IL for parts. Right away i was told they can sell me everything needed except engine bearings. Those were not available at all. I could have went next door to Imperial Jaguar but I had a better idea in mind. I contacted ACL bearing company to discuss custom bearing options. In the end of the day I was able to source main and rod bearing in tri-metal contruction from the ACL Race Series.

Original fasteners in the engine were torque to yield design. This means fasteners have to be replaced every time then are tightened and loosened. Official Jaguar and Aston Marin literature suggest main and head studs can only be tightened 2 times before requiring replacement. I contacted ARP for custom fasteners. Head stud option from ARP was possible at a cost of almost $1000 for a set. It did not seem bad for custom made studs but the lead time of almost 10 weeks was a definite turn-off. I talked to ARP about main stud as well and they were of great help. They were able to provide main studs at a very reasonable price and short lead time.

I contacted CP/Carillo for forged piston and connecting rod option. Cylinder bores were worn and AM does not offer an oversize piston option from the dealer. I sent a sample piston, pin, clips, and ring pack to CP for measurements. Three weeks later I had a set of forged piston in 0.5mm oversize. Carillo made a set of connecting rods as well. They are H-beam design and actually lighter weight than the stock powder metal units. Carillo rods were made in custom small end size, crankshaft rod journal was machined in custom size, so that an off-the-shelf ACL Race Series rod bearing could be used.

There was a lot of machining involved in repair of this engine. Oil starvation cause then engine to seize, crankshaft damage, camshaft damage, and cylinder head journal damage.

Block machining:

1. cylinders bored/plateau honed

2. crankshaft main journals align honed

Crankshaft:

1. rod journals spray welded

2. rod journals reground to custom size

3. main journals reground 0.010" under also for custom size bearings

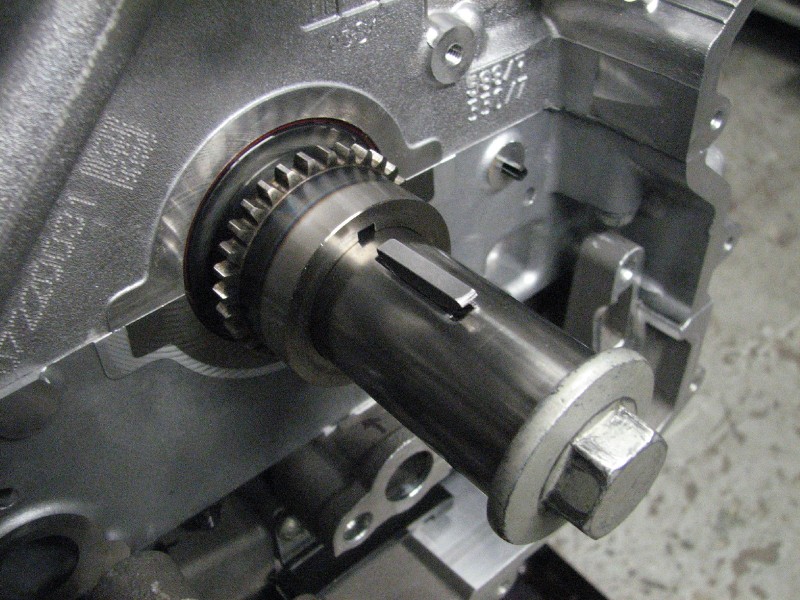

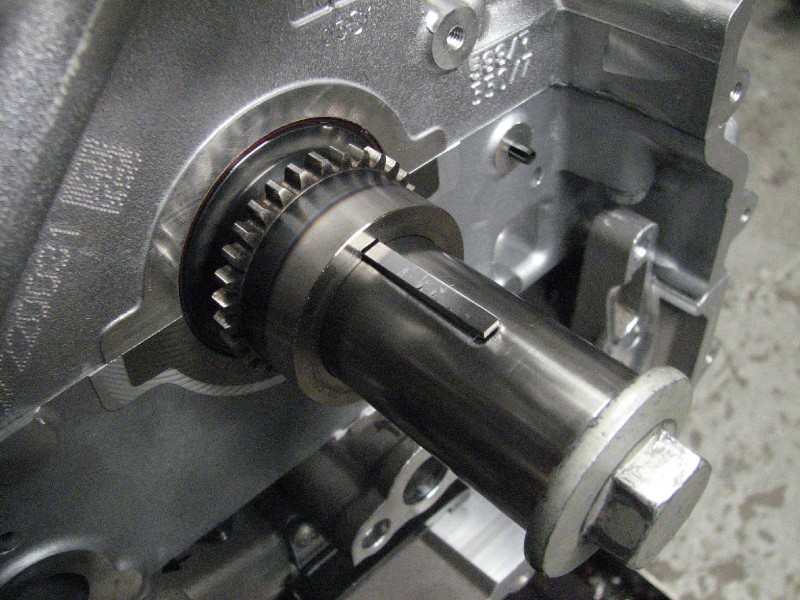

4. custom wood-ruff key machined from 4140 chrome molybdenum steel used for retaining oil pump gear

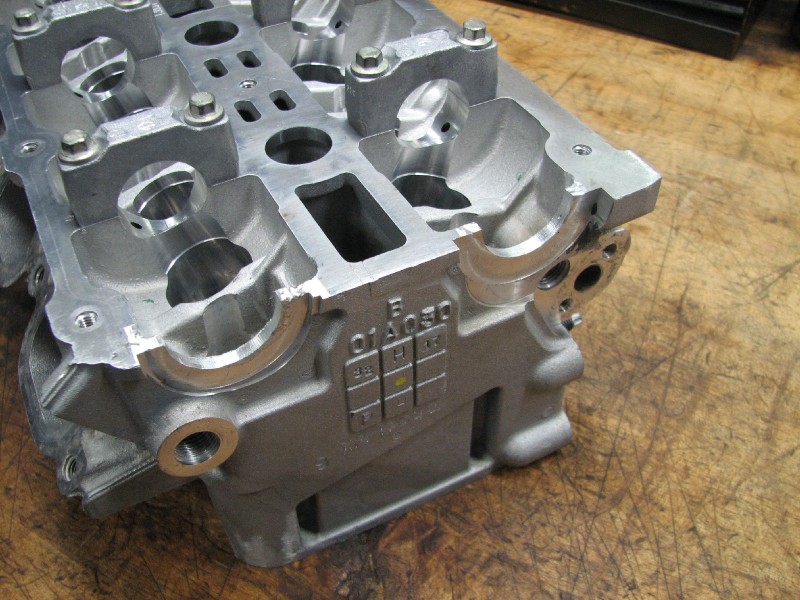

Cylinder heads:

1. camshaft journals polished(luckily did not require grinding)

2. cylinder head journals align hone to size(way too much oil clearance)

3. cylinder head machined for exit of align hone mandrel in Bridgeport mill

4. cylinder head plugs machine in a CNC to be used after head is align honed

Pictures say a 1000 words so I will proceed.

Engine disassembled for inspection to find the following carnage:

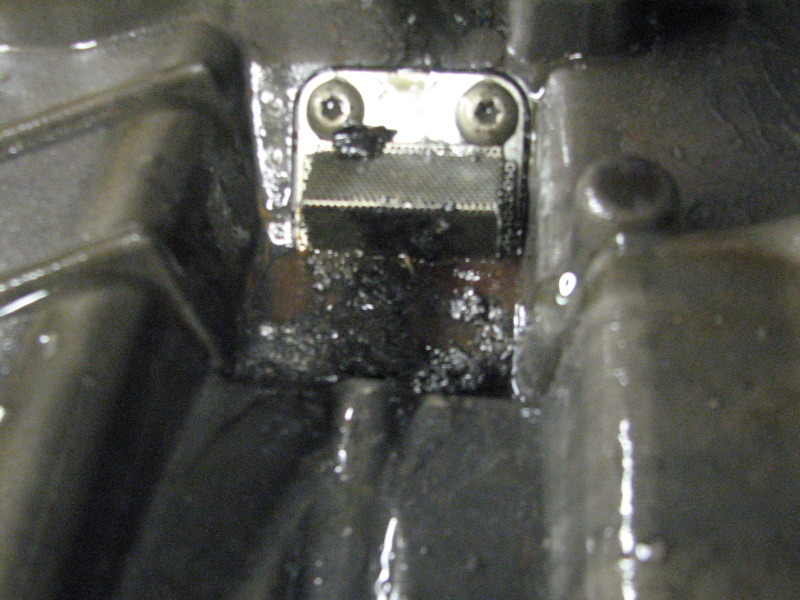

metal in the oil pan

This is how pistons looked

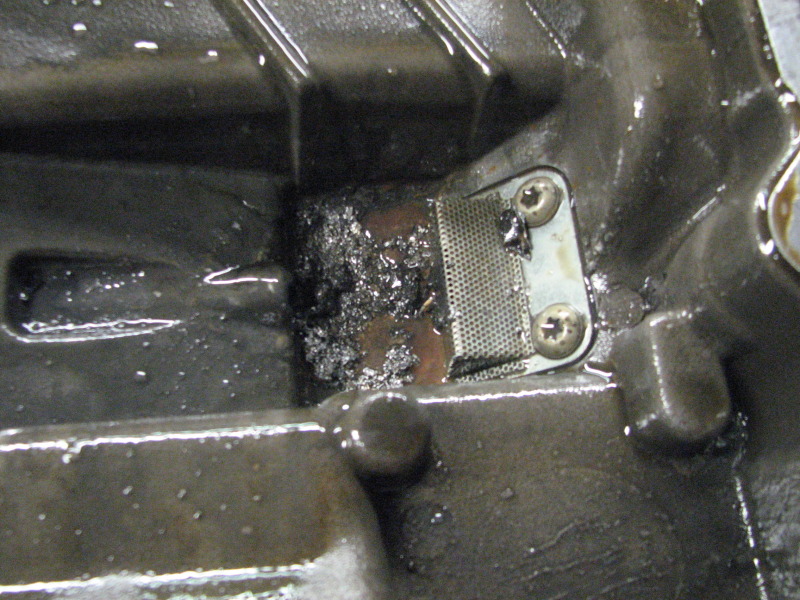

Disassemled the oil pumps and rotors were worn

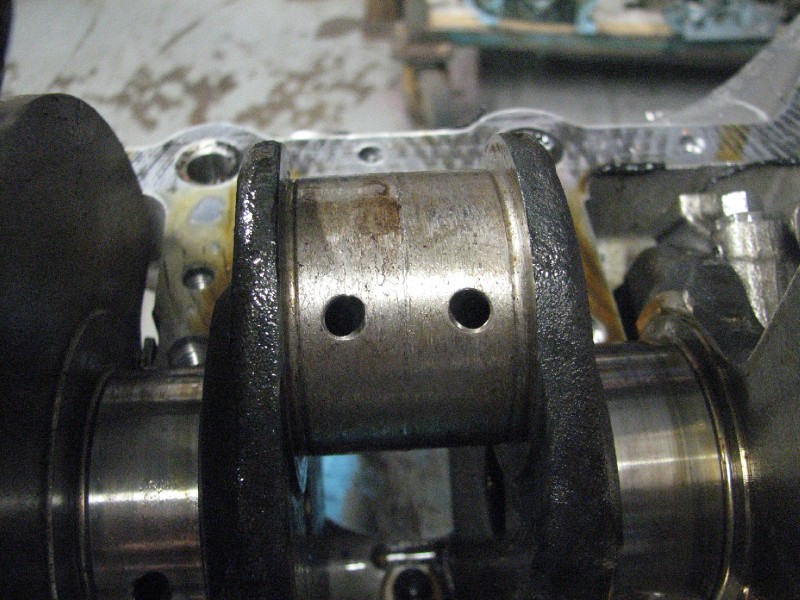

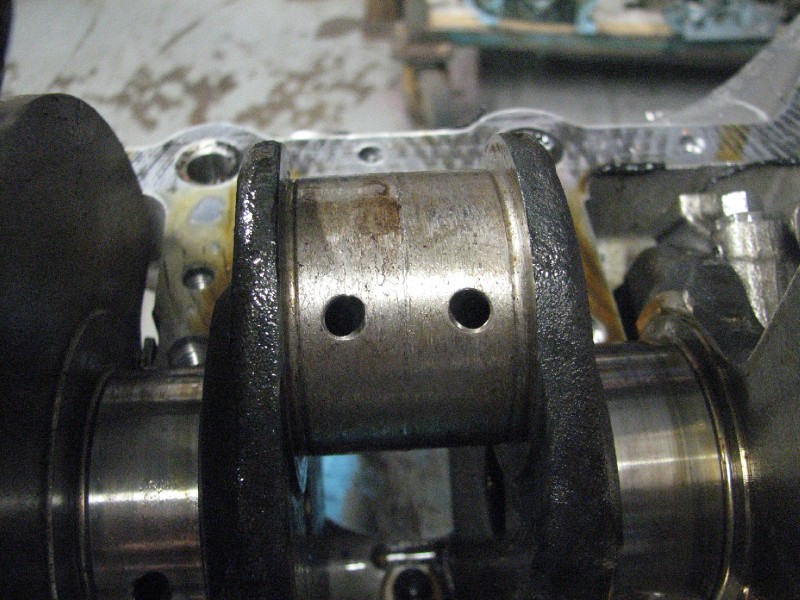

Crankshaft journals

#3 rod pin was damaged the most requiring spray welding and regrinding

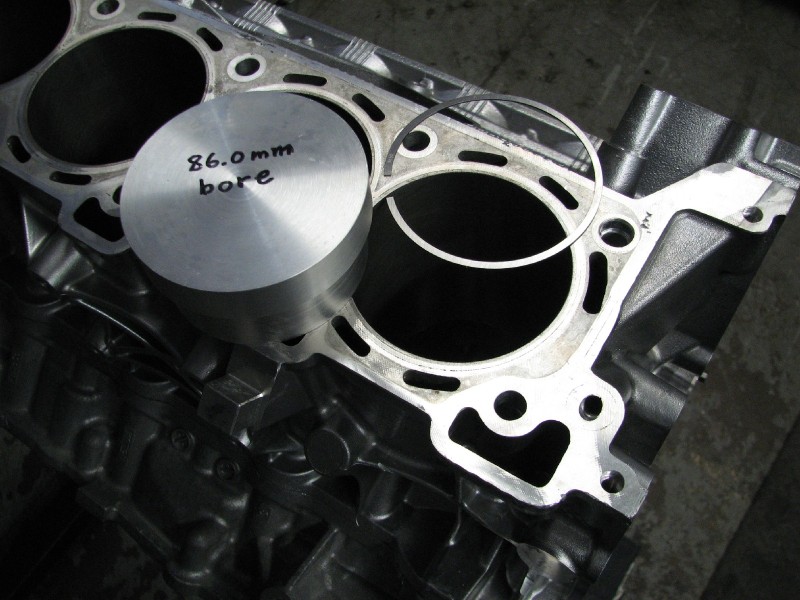

Custom forged piston from CP (comparison to stock)

Custom forged connecting rods from Carillo (comparison to stock AM 4.7 and jaguar 4.2)

Crankshaft after machining and plasma nitride treatment

Complete rotating assembly

Checking piston ring gap

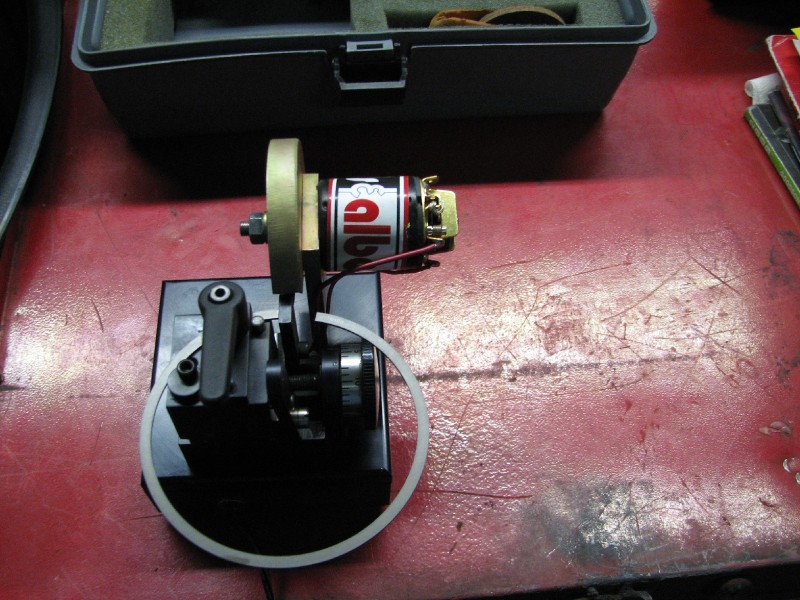

Filing piston ring gap with a grinder

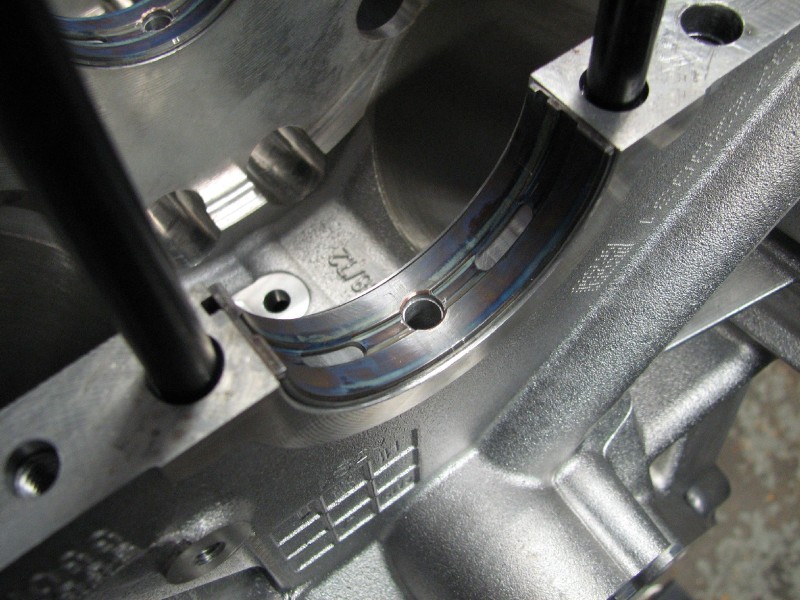

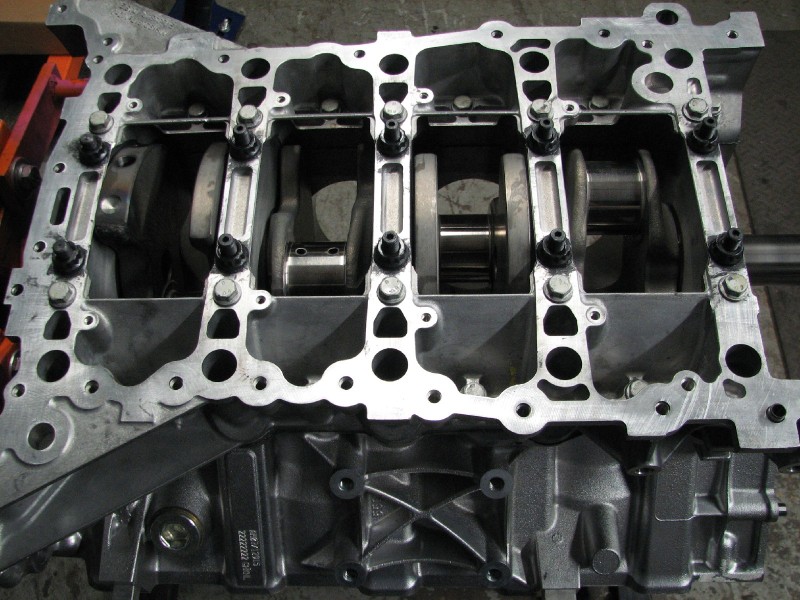

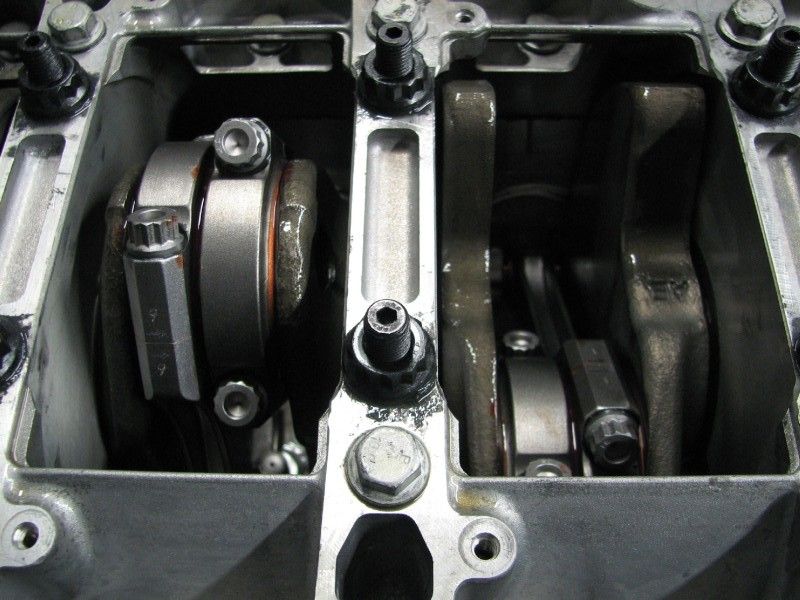

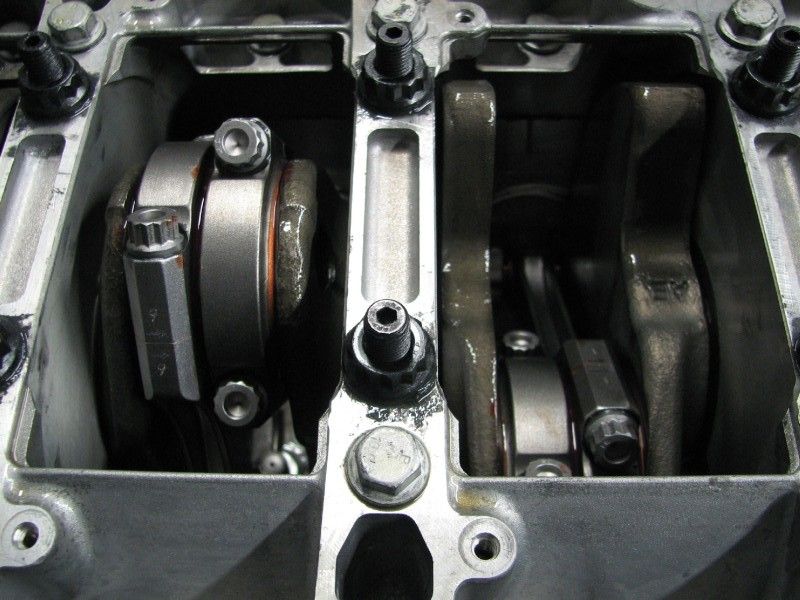

ACL Race Series main bearing close-up

ARP main studs

next time I would like to machine out the small M8 outer studs and convert them to M10 just like the ARP inner studs. This will make for a tru 4 bolt main engine.

Girdle tighetened

Rods on the crankshaft

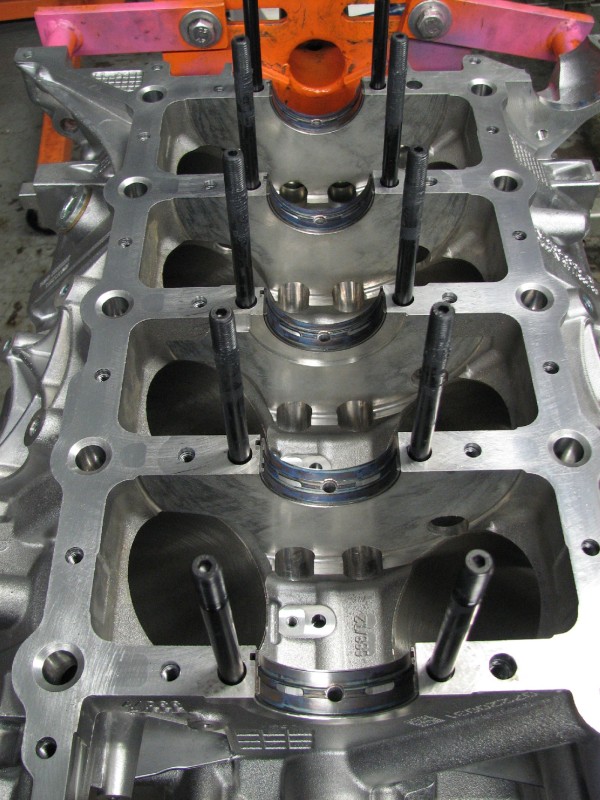

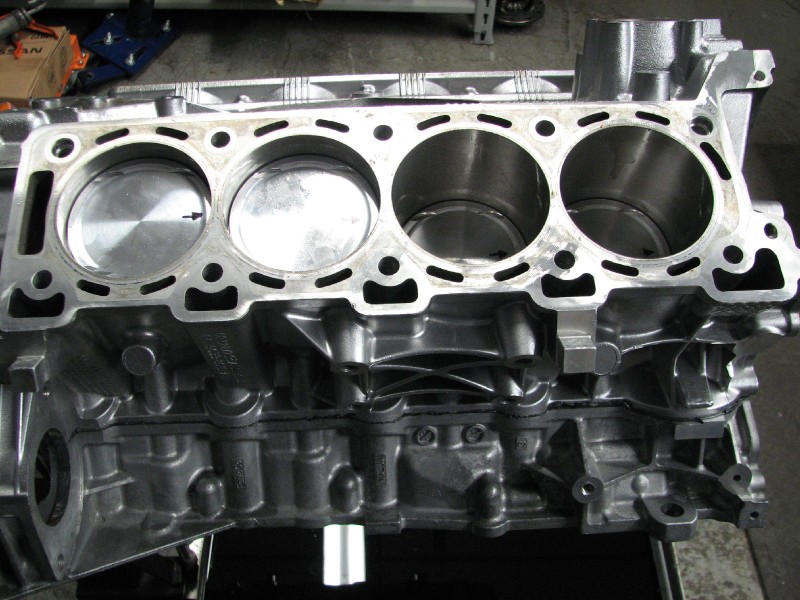

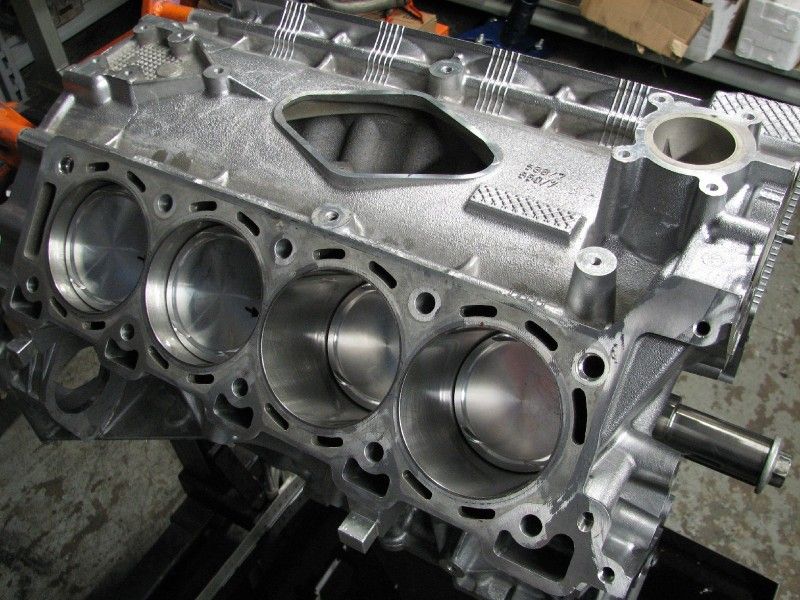

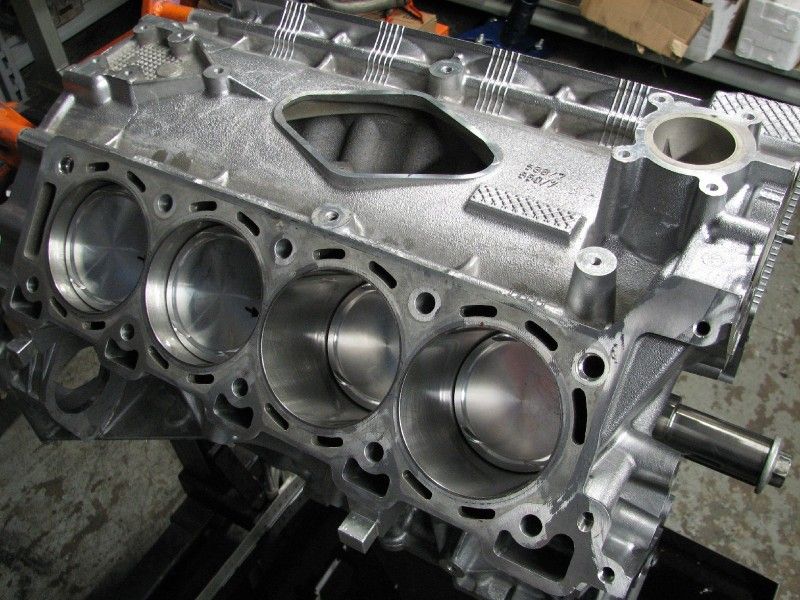

Pistons in block

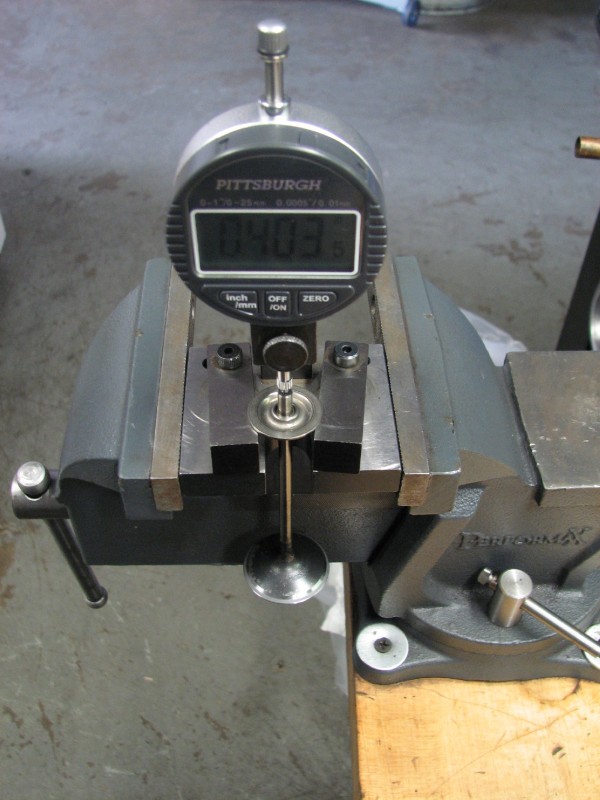

Rod bolts tightened using a rod bolt stretch gauge, not a torque wrench. This is a more accurate method.

Machining performed on the rear of both cylinder heads to allow align hone mandrel to overstroke the journals

CNC machined inserts that were later cut in half and used as plugs in the back of the cylinder heads

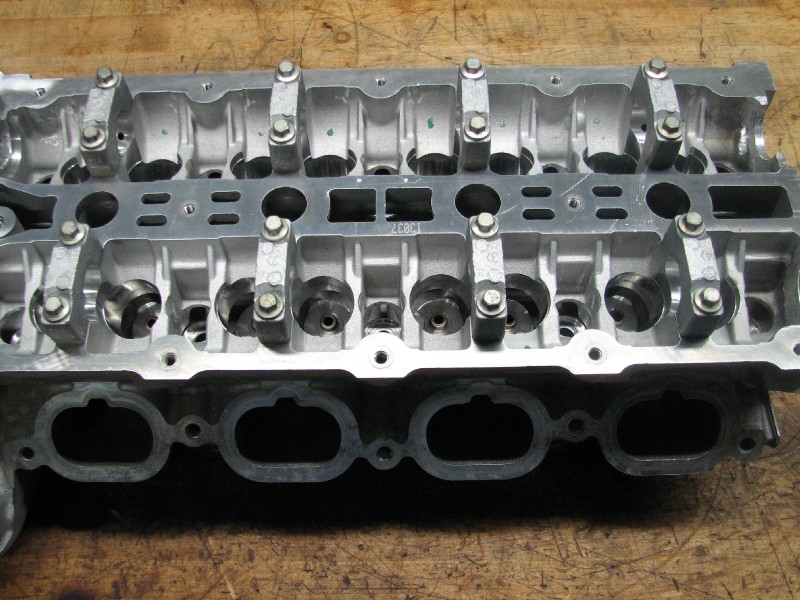

All valves refaced using a Sunnen centerless valve grinder, hand lapped, and seal checked with Prussian blue

Closeup of combustion chamber

Cylinder head with caps on

This fixture was used to measure valve spring install height and check stock valve spring pressures

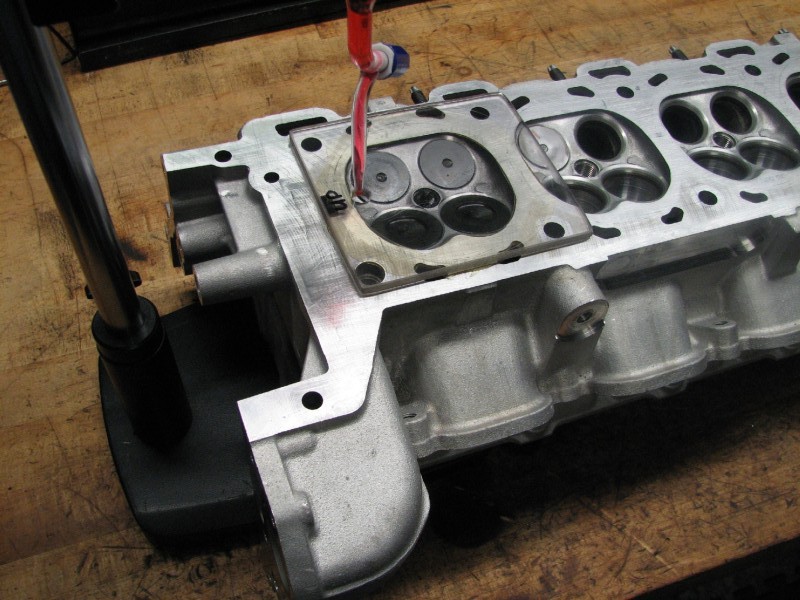

Combustion chamber and piston dish volume measured and exact compression ratio calculated and confirmed

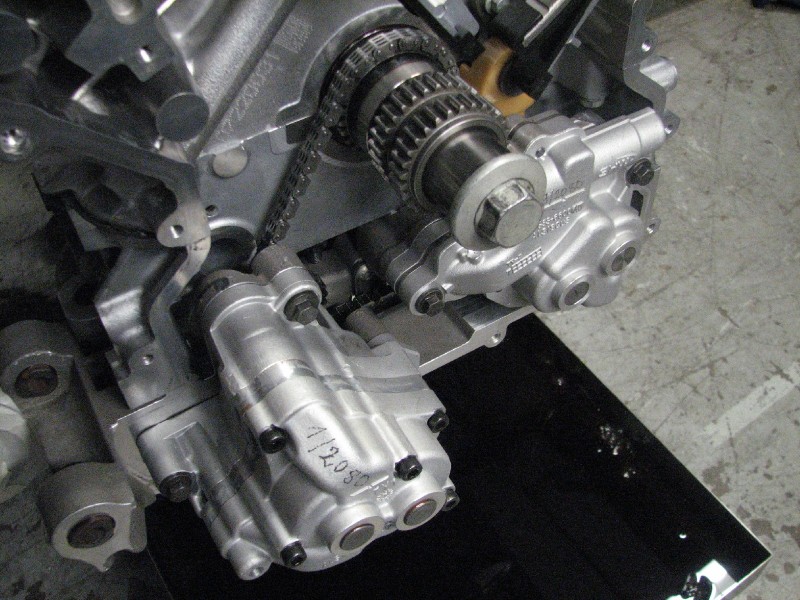

Aston martin does not positively fix the oil pump drive gear to the crankshaft. This gear is held in place by friction and the torque when it is pressed between the timing chain gear and the crankshaft sprocket. If the crankshaft pulley bolt loosens the engine will keep spinning but the oil pumps will stop, causing catastrophic engine failure. This billet 4140 wood-ruff key was made to retain the timing chain gear and oil pump gear together. Next time I would like to machine the crankshaft snout to accept a full size key.

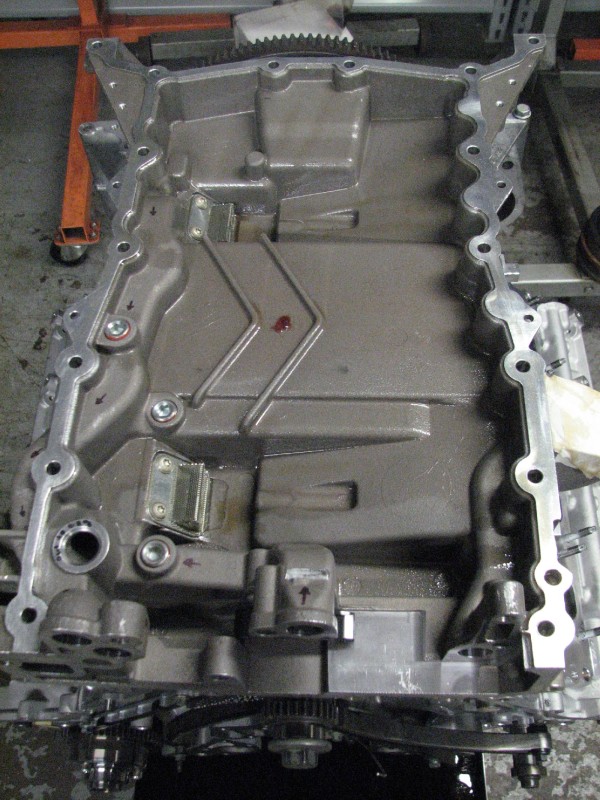

Cleaned dry sump oil pan

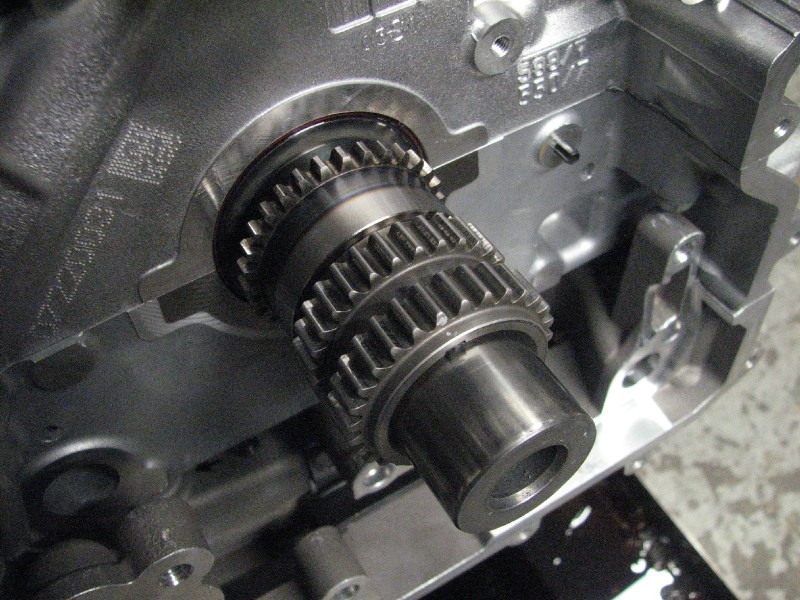

Dry sump oil pumps installed

Engine assembled and camshaft degreed

So far the engine has 2,000 miles and runs flawlessly. The car had to go back to the dealer only to have the transmission recalibrated. Flywheel was lightly resurfaced and the clutch engagement point had to be calibrated by a tech.

I would like to document an engine rebuild I did this summer on a 2009 Aston Martin Vantage V8 4.7. Engine was seized due to oil starvation and spun main bearings. Even with all bolts loose on the main bearing girdle and me hanging on a 3 foot breaker bar off the crank pulley it would not turn.

I called Lake Forest Sports Cars in Lake Forest, IL for parts. Right away i was told they can sell me everything needed except engine bearings. Those were not available at all. I could have went next door to Imperial Jaguar but I had a better idea in mind. I contacted ACL bearing company to discuss custom bearing options. In the end of the day I was able to source main and rod bearing in tri-metal contruction from the ACL Race Series.

Original fasteners in the engine were torque to yield design. This means fasteners have to be replaced every time then are tightened and loosened. Official Jaguar and Aston Marin literature suggest main and head studs can only be tightened 2 times before requiring replacement. I contacted ARP for custom fasteners. Head stud option from ARP was possible at a cost of almost $1000 for a set. It did not seem bad for custom made studs but the lead time of almost 10 weeks was a definite turn-off. I talked to ARP about main stud as well and they were of great help. They were able to provide main studs at a very reasonable price and short lead time.

I contacted CP/Carillo for forged piston and connecting rod option. Cylinder bores were worn and AM does not offer an oversize piston option from the dealer. I sent a sample piston, pin, clips, and ring pack to CP for measurements. Three weeks later I had a set of forged piston in 0.5mm oversize. Carillo made a set of connecting rods as well. They are H-beam design and actually lighter weight than the stock powder metal units. Carillo rods were made in custom small end size, crankshaft rod journal was machined in custom size, so that an off-the-shelf ACL Race Series rod bearing could be used.

There was a lot of machining involved in repair of this engine. Oil starvation cause then engine to seize, crankshaft damage, camshaft damage, and cylinder head journal damage.

Block machining:

1. cylinders bored/plateau honed

2. crankshaft main journals align honed

Crankshaft:

1. rod journals spray welded

2. rod journals reground to custom size

3. main journals reground 0.010" under also for custom size bearings

4. custom wood-ruff key machined from 4140 chrome molybdenum steel used for retaining oil pump gear

Cylinder heads:

1. camshaft journals polished(luckily did not require grinding)

2. cylinder head journals align hone to size(way too much oil clearance)

3. cylinder head machined for exit of align hone mandrel in Bridgeport mill

4. cylinder head plugs machine in a CNC to be used after head is align honed

Pictures say a 1000 words so I will proceed.

Engine disassembled for inspection to find the following carnage:

metal in the oil pan

This is how pistons looked

Disassemled the oil pumps and rotors were worn

Crankshaft journals

#3 rod pin was damaged the most requiring spray welding and regrinding

Custom forged piston from CP (comparison to stock)

Custom forged connecting rods from Carillo (comparison to stock AM 4.7 and jaguar 4.2)

Crankshaft after machining and plasma nitride treatment

Complete rotating assembly

Checking piston ring gap

Filing piston ring gap with a grinder

ACL Race Series main bearing close-up

ARP main studs

next time I would like to machine out the small M8 outer studs and convert them to M10 just like the ARP inner studs. This will make for a tru 4 bolt main engine.

Girdle tighetened

Rods on the crankshaft

Pistons in block

Rod bolts tightened using a rod bolt stretch gauge, not a torque wrench. This is a more accurate method.

Machining performed on the rear of both cylinder heads to allow align hone mandrel to overstroke the journals

CNC machined inserts that were later cut in half and used as plugs in the back of the cylinder heads

All valves refaced using a Sunnen centerless valve grinder, hand lapped, and seal checked with Prussian blue

Closeup of combustion chamber

Cylinder head with caps on

This fixture was used to measure valve spring install height and check stock valve spring pressures

Combustion chamber and piston dish volume measured and exact compression ratio calculated and confirmed

Aston martin does not positively fix the oil pump drive gear to the crankshaft. This gear is held in place by friction and the torque when it is pressed between the timing chain gear and the crankshaft sprocket. If the crankshaft pulley bolt loosens the engine will keep spinning but the oil pumps will stop, causing catastrophic engine failure. This billet 4140 wood-ruff key was made to retain the timing chain gear and oil pump gear together. Next time I would like to machine the crankshaft snout to accept a full size key.

Cleaned dry sump oil pan

Dry sump oil pumps installed

Engine assembled and camshaft degreed

So far the engine has 2,000 miles and runs flawlessly. The car had to go back to the dealer only to have the transmission recalibrated. Flywheel was lightly resurfaced and the clutch engagement point had to be calibrated by a tech.

#4

No port work. I planned to put the head on a flow bench but ran out of time. The goal was a stock rebuild with better than stock reliability. This engine was not intended for performance purposes, although the block is now built to handle it.

CP/Carillo rated all their components to about 800-900hp.

When boring and honing aluminum blocks usually it is best to do so with torque plates simulating cylinder distortion as though the heads are fastened to the block. The guy opted out of paying for machining time and material to make torque plates. I was a bit concerned since it can make for a noisier engine with forged pistons. Surprisingly it was not the case. The block is very rigid.

Here is an example of torque plates I made for boring/honing a Hyundai Genesis Coupe 3.8L V6. Those engines are extremely fluid. You can have a round cylinder when torque plates are on and when you take them off the bores can go out of round by as much as 0.001" inch.

Last edited by Pavel; 12-25-2012 at 03:31 PM.

#5

Nice work...devil is in the details you've carefully looked thru all the details and gained valuable experience. Do you work on the v12 aston engines also, or just the v8? Are you an enthusiast who rebuilds motors and so forth, you are quite skilled it seems.

#6

I like to think of myself as someone who takes on these types of projects out personal interest and sheer engineering challenge compared to what I do on daily basis ;-)

#7

@Pavel, Can you share the story behind the oil starvation? Mechanical failure or operator error?

Trending Topics

#8

The 2009 Jaguar XF supercharged 4.2L V8 I did before had the same exact rod knock/failure on #3 rod pin. That particular engine failure was 100% operator negligence. The guy use to start the car, even during winter, and drive it full throttle right away.

Seeing almost identical damage leads me to conclude that both engines were neglected leading to failures.

Aston Martin does not list a specification for bearing clearances in their service manual. I bought several different grade Jaguar bearing shells and checked clearances. It seems they use 0.0008-0.0011" inch for clearance. It can be as tight as 0.0004". When this engine was rebuilt I had the main bearing clearance set a bit more loose and use higher viscosity oil. SynMax 10W-45 was used for break-in and Valvoline VR1 20W-50 as a regular change.

The Jaguar engine has about 10,000 miles on it now and serviced using Schaiffer's 5W-20 synthetic. SO far so good as well.

Note:

Aluminum block engines are designed with very tight main bearing clearances. A lot of engines are made with less than 0.001" inch clearance. As comparison: one hair has a thickness or 0.003" inch. These modern engines are made to be very tight when cold because as the engine reaches operating temperature it expands and clearances increase. Some engines main housings can expand as much as 0.001". If you machine the block to be "loose" when cold it will be even more "loose" when hot, leading to very low oil pressure and engine damage. Aluminum block engines have to be warmed up before heavy use.

#10

Fantastic thread!!!! Amazing fountain of knowledge.

I have heard of a 4 astons lately (two of them V12s) with the same oil starvation failure problems.... It does have me slightly concerned. Is there anything to look out for and watch for to minimize the odds of that happening?

Thanks

I have heard of a 4 astons lately (two of them V12s) with the same oil starvation failure problems.... It does have me slightly concerned. Is there anything to look out for and watch for to minimize the odds of that happening?

Thanks

#12

Fantastic thread!!!! Amazing fountain of knowledge.

I have heard of a 4 astons lately (two of them V12s) with the same oil starvation failure problems.... It does have me slightly concerned. Is there anything to look out for and watch for to minimize the odds of that happening?

Thanks

I have heard of a 4 astons lately (two of them V12s) with the same oil starvation failure problems.... It does have me slightly concerned. Is there anything to look out for and watch for to minimize the odds of that happening?

Thanks

When I first walked into the AM dealer in Lake Forest they thought I was joking about doing such an ambitious rebuild. When I showed them pictures of the progress and eventually pulled in with the car for transmission software update/recalibration the operations manager at AM gave me his business card and we had a nice 2 hour discussion of his personal Mustang and AM engine problems. He said V12 failures can be mostly traced to the piston ring design chosen by AM. Piston rings wear allowing increased blow-by and oil consumption. That leads to low oil level and eventual engine failure. This sounds all too familiar since Saab in the late 90's and early 2000's had a much similar issue leading to the manufacturer even extending the powertrain warranty.

He had no explanation for V8 engine failures. He said for the most part they were trouble-free, unlike the V12's. So far both V8 failures I encountered seem to have been caused by driver error/neglect.

Since V12 have known problems as he mentioned it would be wise to replace stock pistons with forged units, along with new performance oriented rings. While at it replacement of connecting rods is a good idea as well. So far all Jaguar and Aston Martin rods I have seen are powder steel construction. They are not made for high performance use. They are cheap to make and that's why they were chose by AM(or Ford if you will).

Considering the cost of rods and pistons versus a hole in the block or seized motor it is a fraction of the cost.

#14

In short no, long winded explanation below.

Jaguar XF 4.2L engine has a bore of 86mm and stroke of 90.3mm

Vantage 4.3L engine has a bore of 89mm and stroke of 86mm

Vantage 4.7L engine has a bore of 91mm and stroke of 91mm(different crankshaft)

Vantage engines have aluminum blocks with pressed in iron liners. I'm not sure of the liner thickness of the 4.3L engine. Only way to find out is to use a sonic thickness tester and actually check. I'm not sure stock iron sleeve can be safely bore out an extra 2mm(from 89mm to 91mm).

Quick Displacement Check:

stock 4.3L(89mm bore/86mm stroke): 4280cc

stock 4.7L(91mm bore/91mm stroke): 4735cc

4.3L engine with 91mm bore and stock crank(86mm): 4474cc (basically a 4.5L)

short stroke of the 4.3L crankshaft is the limiting factor. It is possible to have a 4.7L displacement by installing a 4.7L crank in a 4.3L block. Last i checked AM wanted about $4000 for a new crankshaft. It is a rather nice piece but for that kind of money you can easily budget a much stronger custom made 4340 chrome molybdenum steel crankshaft.

Here is food for thought...

4.7L engine bored to 93mm(91mm stock) and standard 91mm stroke: 4945cc... 5 LITER VANTAGE!!!

This will require custom sleeves to be made and pressed into the block.... details of course.

Jaguar XF 4.2L engine has a bore of 86mm and stroke of 90.3mm

Vantage 4.3L engine has a bore of 89mm and stroke of 86mm

Vantage 4.7L engine has a bore of 91mm and stroke of 91mm(different crankshaft)

Vantage engines have aluminum blocks with pressed in iron liners. I'm not sure of the liner thickness of the 4.3L engine. Only way to find out is to use a sonic thickness tester and actually check. I'm not sure stock iron sleeve can be safely bore out an extra 2mm(from 89mm to 91mm).

Quick Displacement Check:

stock 4.3L(89mm bore/86mm stroke): 4280cc

stock 4.7L(91mm bore/91mm stroke): 4735cc

4.3L engine with 91mm bore and stock crank(86mm): 4474cc (basically a 4.5L)

short stroke of the 4.3L crankshaft is the limiting factor. It is possible to have a 4.7L displacement by installing a 4.7L crank in a 4.3L block. Last i checked AM wanted about $4000 for a new crankshaft. It is a rather nice piece but for that kind of money you can easily budget a much stronger custom made 4340 chrome molybdenum steel crankshaft.

Here is food for thought...

4.7L engine bored to 93mm(91mm stock) and standard 91mm stroke: 4945cc... 5 LITER VANTAGE!!!

This will require custom sleeves to be made and pressed into the block.... details of course.

#15

As a guy who works on his own cars thats pretty cool you took on that project seeing there isn't many resources out there for these cars and most of the dealers pretty much laugh you off. I have never tried to rebuild an exotic engine but it seems odd that Aston did not include tolerances on any of the engine parts in the shop manual. Just out of curiosity what did the rebuild cost?