Top Gear Tours the Magical Factory That Builds Koenigseggs

From the all-new Jesko to the Regera, Koenigsegg’s hangar home unleashes the finest machines never to fly in the sky.

Seeing where the finest cars in the world are made is always an unforgettable time. Whether it’s Ferrari’s home in Maranello, Italy, the high-tech confines of Tesla’s facility in California, or the birthing ward of the Nissan GT-R in the company’s Tochigi, Japan, the magic behind our favorite cars is everlasting.

Another such place: Koenigsegg’s hangar and runway in Ängelholm, Sweden, where SAAB Viggen fighters once took to the skies. Today, cars like the Regera and the recently introduced Jesko work out their kinks on the runway before heading off to their new homes. Top Gear‘s Jack Rix recently got a look at the Jesko, along with all that goes on inside the old military base.

“Finding the factory is easy,” said Rix. “Take the turn at the SAAB Viggen jet — how cool is that — keep going past the surface-to-air missile, and keep your eyes peeled for an enormous green shed. In fact, it’s an aircraft hangar that used to belong to ‘The Ghosts,’ Sweden’s oldest fighter plane squadron; hence, Koenigsegg’s logo. Admire the wonderful and extremely orange CCX-R in reception, and you’re there.”

“The working name for this project for the last three years has been ‘Ragnarök,’ said Koenigsegg’s namesake and CEO Christian von Koenigsegg, “which is like this Norse, end-of-the-world. Our sales director, Andreas Petri, who’s a very good friend of my father, he said, ‘We should honor your father.'”

ALSO SEE: Bugatti Chiron Drive Review: 1,500 Horsepower of Engineering Excellence

Jesko von Koenigsegg helped his son build up their namesake company in its early years, serving on the board for a couple of those years while the company established a firm foundation in the supercar scene.

The $2.8-million Jesko seen in the video being prepped for the Geneva Motor Show this year isn’t the one that will hit 300 mph, according to von Koenigsegg, mainly due to the big wing in the back creating too much drag for that to happen. Instead, the Jesko 300 will take that challenge with a different wing and aero package. He adds that preparing for such a challenge means finding the right car, the right driver, and bringing all of the other elements together at the right time; thus, he’s shooting for a buffer of 310 mph with the Jesko 300.

“Here’s a little bit of a brucey bonus that we weren’t expecting today; I suppose these sort of things happen when you spend the day at the Koenigsegg factory,” said Rix. “Basically, they were needed to do a little bit of tuning work, a little bit of running-in on one of the Regeras, one of the 80 cars that they’re building. They said, ‘Jack, do you wanna jump in the passenger seat? We’re gonna head down the runway and blast about in a Regera.’ I wasn’t about to say no.”

After the zero to 186 mph to zero run in the 1,500-horsepower Regera, Rix heads back into the factory to check out the rest of the magic at Koenigsegg. His first stop was the carbon fiber workshop, where 30% to 40% of the Regera’s and Jesko’s smaller carbon fiber parts are first created; the rest are made in Spain. A computer is used to create a given part, which is then cut from the sheets, then placed on an aluminum mold for shaping before sent into an oven to bake for up to five hours at 120 degrees F.

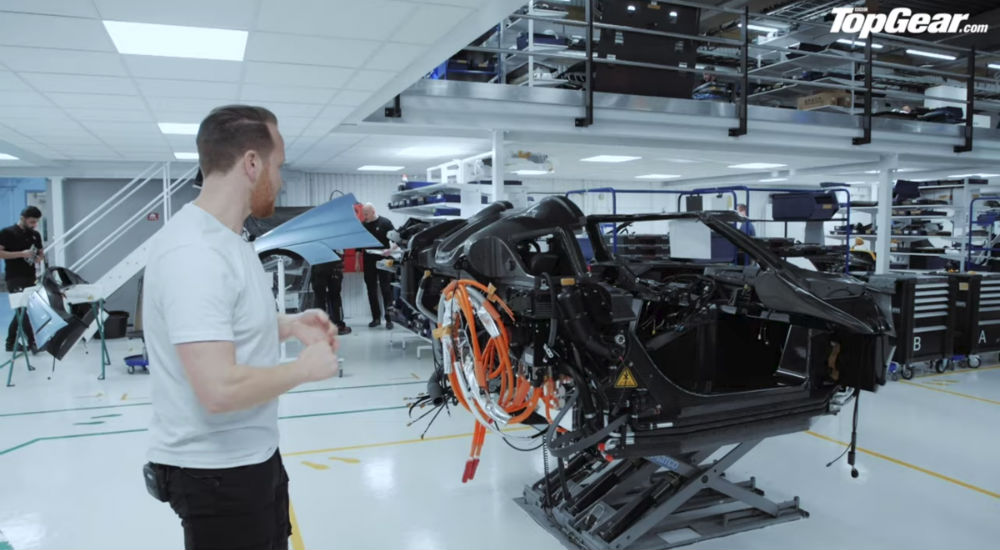

“Alright. Now we’re talking,” said Rix. “Getting to the really big stuff. This is a chassis, effectively built up of three or four big main structural elements. You got the floor pan down here. You’ve got the fuel cell, these side pods that runs across the back, runs down the other side, super strong — strongest bit of the car so it keeps the fuel low, and keeps it nice and safe.”

ALSO SEE: Lamborghini Huracan Performante Spyder Drive Review: Wild, Insane, Perfect

Rix notes how the windshield frame, in particular, is as strong as they come, despite looking like it could snap in half. The whole chassis is the strongest unit in the industry, boasting more torsional stiffness than a Bugatti Chiron.

After the chassis and other body pieces are ready to go, they’re all fitted upon a wooden buck to check for panel gaps, and for painters to apply marks for painting stripes prior to the body parts heading off to the paint booth. Painting a full car takes anywhere from 600 to 800 hours, according to Rix, from prep to the act itself. The body, meanwhile, gets some polishing where needed, as do the aluminum parts, which are kept in individual cases. The polishing process adds another 200 hours to the overall build.

The cars are then assembled in individual bays throughout the floor, where everything from the 800-volt electrical systems to the 5.0-liter V8s and body panels come together at last.

“That is how a hypercar is made,” said Rix. “And believe me, I was as skeptical as you are that any car in the world could be worth [$2.5 million to $3.8 million]. But when you come here, when you see the skill, the craftsmanship, and the love that goes into all the components that make this car, you start to believe it’s worth it.”