Volumetric Efficiency Comparo

#46

There's the interplay between equations, real world data, and estimating. Modding is certainly not an exact science or we would be done already. To answer your specific question, this would need to be determined in a R&D setting. No doubt Porsche has the answer since they haved measured crank HP and fuel consumed. For us lay people, it's a guesstimate, except for VE which is derived from all measureable input parameters which is why it's nice.

#47

Hi, I think what you're asking is described nicely on the Garret turbo site with examples. Click here. As far as my understanding goes, you can't really relate the VEs calculated here with what you are asking. Basically, you have to match the turbo with what your motor can flow. Obviously, if you slap on a big honking turbo and your motor can't flow enough air to spin the turbine adequately, it will do you no good. So those equations are meant to be used to put you in the right ballpark in choosing a turbo if you were starting from scratch. Fortunately, we have a ton of real-world data to rely on.

After you add the turbo's, the VEs obviously go up. We're are measuring VEs for different set-ups, post-mod. The goal, of course, is to maximize VEs across the rpm power range. You could measure VEs after installing different supporting mods like ICs to see which might be more effective under different conditions. Just because an IC may be controlling IATs better at X hp does not mean that it will be suitable at higher hp due to flow restrictions. VEs will tell you this.

After you add the turbo's, the VEs obviously go up. We're are measuring VEs for different set-ups, post-mod. The goal, of course, is to maximize VEs across the rpm power range. You could measure VEs after installing different supporting mods like ICs to see which might be more effective under different conditions. Just because an IC may be controlling IATs better at X hp does not mean that it will be suitable at higher hp due to flow restrictions. VEs will tell you this.

As for the link to the Gerrett site, it's very usefull, thanks...

I need you to comment a bit on this one though:

Where:

· MAPreq = Manifold Absolute Pressure (psia) required to meet the horsepower target

· Wa = Airflowactual(lb/min)

· R = Gas Constant = 639.6

· Tm = Intake Manifold Temperature (degrees F)

· VE = Volumetric Efficiency

· N = Engine speed (RPM)

· Vd = engine displacement (Cubic Inches, convert from liters to CI by multiplying by 61.02, ex. 2.0 liters * 61.02 = 122 CI)

In this formula, the required manifold pressure to obtain a given HP figure, it's only related to the engine's features and Intake manifold Temp. (affected by compressor efficiency and compression ratio, given a fixed intercooling efficiency).

I get the sense of it perfectly, BUT, why do we see (in real world) big turbos making more power than smaller ones at a given boost level?

May be that bigger turbos are often coupled with other "supporting" mods that affect volumetric efficiency and that they have better efficiency than smaller turbos at the same comp. ratio?

Sorry if my questions seem stupid, but I'm not used to learn formulas without knowing where they come from.

PS:any book suggestion on the subject would be MUCH appreciated..

Last edited by emadelta86; 01-04-2011 at 01:05 PM.

#48

There's the interplay between equations, real world data, and estimating. Modding is certainly not an exact science or we would be done already. To answer your specific question, this would need to be determined in a R&D setting. No doubt Porsche has the answer since they haved measured crank HP and fuel consumed. For us lay people, it's a guesstimate, except for VE which is derived from all measureable input parameters which is why it's nice.

Uhmmmm.......... I was hoping some one might have said that Durametric can determine the injector rate with a given pressure and injector cc size the squirt of fuel could be calculated.

Frank

#50

If you know how long your injectors are open and fuel pressure ( and of course fuel's density ), you can calculate the fuel consumption rate. For power produced you'll need an engine dyno.

#52

Wouldn't it be simpler using AFR and MAF+air temp+baro pressure readings?On a dyno, you can measure power, then take MAF reading from the datalog, ambient air temp and barometric pressure (=air density), AFR with a wideband or with datalog lambda reading, and there you go.

#53

Now it gets interesting

So I got the values for my car when standard. I have plot these VE figures against two other cars that I have data for to hand. The question is whether there can be a correlation applied to known tq for standard 996 turbo for the VE figures, that could then be applied to show the tq of the other cars?

#54

Wouldn't it be simpler using AFR and MAF+air temp+baro pressure readings?On a dyno, you can measure power, then take MAF reading from the datalog, ambient air temp and barometric pressure (=air density), AFR with a wideband or with datalog lambda reading, and there you go.

So I got the values for my car when standard. I have plot these VE figures against two other cars that I have data for to hand. The question is whether there can be a correlation applied to known tq for standard 996 turbo for the VE figures, that could then be applied to show the tq of the other cars?

#55

Okay about to be shot down but here goes

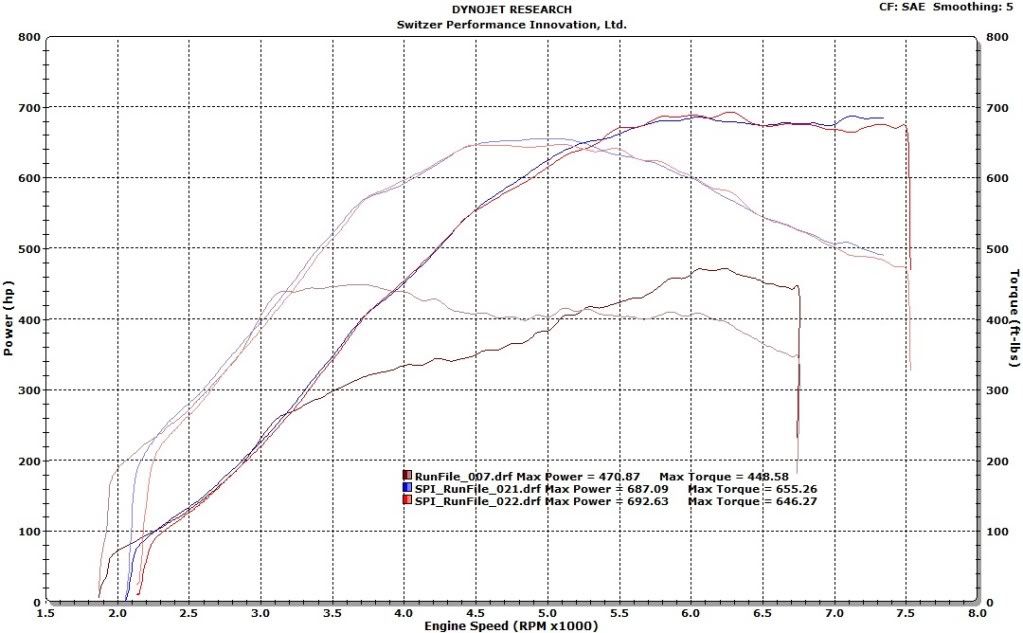

So as I showed on the previous image, I have the VE for std 996, x50 stage1, and my car.

If I correlate the VE for the std 996 to actual torque values supplied by Porsche, and then use the same correlation factor to the other VE, this is what happens. I have plotted HP as well from the TQ calculated.

So what do we think?

I can tell you the x50 is definitely from performance showing around 540hp on testing up to 300kph. The x50 figures don't look too bad in terms of what you would expect from stage 1 map, dvs, exhaust, filter etc.

If I correlate the VE for the std 996 to actual torque values supplied by Porsche, and then use the same correlation factor to the other VE, this is what happens. I have plotted HP as well from the TQ calculated.

So what do we think?

I can tell you the x50 is definitely from performance showing around 540hp on testing up to 300kph. The x50 figures don't look too bad in terms of what you would expect from stage 1 map, dvs, exhaust, filter etc.

#56

So as I showed on the previous image, I have the VE for std 996, x50 stage1, and my car.

If I correlate the VE for the std 996 to actual torque values supplied by Porsche, and then use the same correlation factor to the other VE, this is what happens. I have plotted HP as well from the TQ calculated.

So what do we think?

I can tell you the x50 is definitely from performance showing around 540hp on testing up to 300kph. The x50 figures don't look too bad in terms of what you would expect from stage 1 map, dvs, exhaust, filter etc.

If I correlate the VE for the std 996 to actual torque values supplied by Porsche, and then use the same correlation factor to the other VE, this is what happens. I have plotted HP as well from the TQ calculated.

So what do we think?

I can tell you the x50 is definitely from performance showing around 540hp on testing up to 300kph. The x50 figures don't look too bad in terms of what you would expect from stage 1 map, dvs, exhaust, filter etc.

#57

This example seems right on. From performance data, you estimate 540bhp and the graph show this. That's one data point. I'd say we need about 10 more examples to make this a statistically relevant exercise. The data is only as accurate as the dyno from which it is calibrated. Once you have a good calibrated VE curve, you can probably use that to test the quality of the dyno--lol.

Going to map some more cars into the graph.

#58

Thank you very much!It makes sense now...

As for the link to the Gerrett site, it's very usefull, thanks...

I need you to comment a bit on this one though:

Attachment 140811

Where:

· MAPreq = Manifold Absolute Pressure (psia) required to meet the horsepower target

· Wa = Airflowactual(lb/min)

· R = Gas Constant = 639.6

· Tm = Intake Manifold Temperature (degrees F)

· VE = Volumetric Efficiency

· N = Engine speed (RPM)

· Vd = engine displacement (Cubic Inches, convert from liters to CI by multiplying by 61.02, ex. 2.0 liters * 61.02 = 122 CI)

In this formula, the required manifold pressure to obtain a given HP figure, it's only related to the engine's features and Intake manifold Temp. (affected by compressor efficiency and compression ratio, given a fixed intercooling efficiency).

I get the sense of it perfectly, BUT, why do we see (in real world) big turbos making more power than smaller ones at a given boost level?

May be that bigger turbos are often coupled with other "supporting" mods that affect volumetric efficiency and that they have better efficiency than smaller turbos at the same comp. ratio?

Sorry if my questions seem stupid, but I'm not used to learn formulas without knowing where they come from.

PS:any book suggestion on the subject would be MUCH appreciated..

As for the link to the Gerrett site, it's very usefull, thanks...

I need you to comment a bit on this one though:

Attachment 140811

Where:

· MAPreq = Manifold Absolute Pressure (psia) required to meet the horsepower target

· Wa = Airflowactual(lb/min)

· R = Gas Constant = 639.6

· Tm = Intake Manifold Temperature (degrees F)

· VE = Volumetric Efficiency

· N = Engine speed (RPM)

· Vd = engine displacement (Cubic Inches, convert from liters to CI by multiplying by 61.02, ex. 2.0 liters * 61.02 = 122 CI)

In this formula, the required manifold pressure to obtain a given HP figure, it's only related to the engine's features and Intake manifold Temp. (affected by compressor efficiency and compression ratio, given a fixed intercooling efficiency).

I get the sense of it perfectly, BUT, why do we see (in real world) big turbos making more power than smaller ones at a given boost level?

May be that bigger turbos are often coupled with other "supporting" mods that affect volumetric efficiency and that they have better efficiency than smaller turbos at the same comp. ratio?

Sorry if my questions seem stupid, but I'm not used to learn formulas without knowing where they come from.

PS:any book suggestion on the subject would be MUCH appreciated..

#60

The thing is that Todd K told me at 1.5 bar I could expect with my set up somewhere around 660-680whp. I believe that on a tip that the tranny loss is around 28% - anyone have any good figures? So if that is the case, taking 840hp at the crank, and take off the 28% gives around 656 at the wheels. It gets interesting.

Going to map some more cars into the graph.

Going to map some more cars into the graph.