Volumetric Efficiency Comparo

#1

Volumetric Efficiency Comparo

Mike was kind enough to send me a datalog of one his runs. So I compared his VEs (996t, A28s) to mine (997.1t, upgraded vtgs). Mike ran a very fast 5.5s 60-130 (4th gear, 0 shift) and my set-up did a 6.9 (4th, gear, 0 shift). While there is nothing better than real-world data, VEs are interesting in that engine output can be compared without secondary factors like car weight, tailwind, % decline, etc... There is a pretty dramatic difference in VEs as would be expected but look at the low-mid range and area under the curve. Very impressive. For reference, a completely stock 997.1t VE will max out around 185.

Thanks again Mike for sharing your data with me. Happy New Year Bro!

Thanks again Mike for sharing your data with me. Happy New Year Bro!

Last edited by TTdude; 11-17-2013 at 12:02 PM. Reason: op's request

#3

Dave,

Thanks for going to the trouble of calculating and ploting my VE!!

For those of you that dont know Dave, he has a tremendous grasp of the theory and science behind turbocharging and engines. He has tried to show me how to express VE mathematically.

For those of you that are like me, some explanation might be helpful. Volumetric efficiency (in reference to gas engines) is a measure of how well an engine can move air and fuel in and out of the cylinders. It is expressed as a ratio or percentage volume of fuel and air actually admitted into the engine compared to the piston displacement volume. Thinking of an engine as an air pump, the greater power is produced by pumping more air and fuel through the engine/unit time (ie increasing VE).

Typical auto engines run VEs of 85-90%. DOHC, multiple valve/cylinder engines can have VEs above 100% up to 130%. Forced induction engines, like ours, can have VEs approaching 300%.

One point I would add to Dave's plot is that VE in a turbo engine is affected by more factors than just turbo choice. The engine's efficiency is affected by ease of getting air/fuel into and out of the engine ie intake, fuel system, and exhaust flow. Thus, I believe, the above differences in VE probably involve more than just efficiency of A28s vs. modded VTGs.

If you have any questions, ask Dave!!

Thanks for going to the trouble of calculating and ploting my VE!!

For those of you that dont know Dave, he has a tremendous grasp of the theory and science behind turbocharging and engines. He has tried to show me how to express VE mathematically.

For those of you that are like me, some explanation might be helpful. Volumetric efficiency (in reference to gas engines) is a measure of how well an engine can move air and fuel in and out of the cylinders. It is expressed as a ratio or percentage volume of fuel and air actually admitted into the engine compared to the piston displacement volume. Thinking of an engine as an air pump, the greater power is produced by pumping more air and fuel through the engine/unit time (ie increasing VE).

Typical auto engines run VEs of 85-90%. DOHC, multiple valve/cylinder engines can have VEs above 100% up to 130%. Forced induction engines, like ours, can have VEs approaching 300%.

One point I would add to Dave's plot is that VE in a turbo engine is affected by more factors than just turbo choice. The engine's efficiency is affected by ease of getting air/fuel into and out of the engine ie intake, fuel system, and exhaust flow. Thus, I believe, the above differences in VE probably involve more than just efficiency of A28s vs. modded VTGs.

If you have any questions, ask Dave!!

Last edited by MBailey; 01-01-2011 at 12:36 AM.

#7

Dave's going deep into comparing these turbos. + rep for doing the math! This is the data that many members are looking for when one tuner tells us how much better their turbos are.  Better info than a dyno, which fails to show boost threshold and other parameters.

Better info than a dyno, which fails to show boost threshold and other parameters.

Dave, do you have an easier way to calculate this? My understanding is 3 parameters need to be logged from the sensors:

Engine speed, MAF rate, and IAT.

Once you have that info, you calculate for d2

t1 = Temperature of air for a known density (32 °F @ 0.0808 lb/ft3)

t2 = Temperature of the intake air measured by Durametric

d1 = Density of air for a known temperature (0.0808 lb/ft3 @ 32 °F)

d2 = Density of the intake air (lb/ft3)

once you have d2, you can calculate the two major variables for VE:

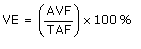

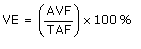

AVF = Actual volumetric flow rate (ft3/minute)

MFk = Mass flow rate taken from Durametric (lb/minute)

d2 = Density of air for the intake air (lb/ft3)

and

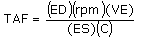

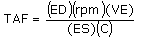

rpm = maximum design rpm

TAF = Theoretical air flow (ft3/minute)

VE = Volumetric efficiency (100% theoretical)

ED = Engine displacement (in3)

ES = Engine stroke (2 for a four stroke engine)

C = Conversion factor from in3 to ft3

to plug into this:

Better info than a dyno, which fails to show boost threshold and other parameters.

Better info than a dyno, which fails to show boost threshold and other parameters.Dave, do you have an easier way to calculate this? My understanding is 3 parameters need to be logged from the sensors:

Engine speed, MAF rate, and IAT.

Once you have that info, you calculate for d2

t1 = Temperature of air for a known density (32 °F @ 0.0808 lb/ft3)

t2 = Temperature of the intake air measured by Durametric

d1 = Density of air for a known temperature (0.0808 lb/ft3 @ 32 °F)

d2 = Density of the intake air (lb/ft3)

once you have d2, you can calculate the two major variables for VE:

AVF = Actual volumetric flow rate (ft3/minute)

MFk = Mass flow rate taken from Durametric (lb/minute)

d2 = Density of air for the intake air (lb/ft3)

and

rpm = maximum design rpm

TAF = Theoretical air flow (ft3/minute)

VE = Volumetric efficiency (100% theoretical)

ED = Engine displacement (in3)

ES = Engine stroke (2 for a four stroke engine)

C = Conversion factor from in3 to ft3

to plug into this:

Last edited by bbywu; 01-01-2011 at 09:32 AM.

Trending Topics

#9

VE expressed in that equation should be 1.00 (theoretical volumetric efficiency.) At least that's how I understand it (I didn't come up with this myself...just info from someone else's explanation.)

bob

bob

#10

Dave,

Thanks for going to the trouble of calculating and ploting my VE!!

For those of you that dont know Dave, he has a tremendous grasp of the theory and science behind turbocharging and engines. He has tried to show me how to express VE mathematically.

For those of you that are like me, some explanation might be helpful. Volumetric efficiency (in reference to gas engines) is a measure of how well an engine can move air and fuel in and out of the cylinders. It is expressed as a ratio or percentage volume of fuel and air actually admitted into the engine compared to the piston displacement volume. Thinking of an engine as an air pump, the greater power is produced by pumping more air and fuel through the engine/unit time (ie increasing VE).

Typical auto engines run VEs of 85-90%. DOHC, multiple valve/cylinder engines can have VEs above 100% up to 130%. Forced induction engines, like ours, can have VEs approaching 300%.

One point I would add to Dave's plot is that VE in a turbo engine is affected by more factors than just turbo choice. The engine's efficiency is affected by ease of getting air/fuel into and out of the engine ie intake, fuel system, and exhaust flow. Thus, I believe, the above differences in VE probably involve more than just efficiency of A28s vs. modded VTGs.

If you have any questions, ask Dave!!

Thanks for going to the trouble of calculating and ploting my VE!!

For those of you that dont know Dave, he has a tremendous grasp of the theory and science behind turbocharging and engines. He has tried to show me how to express VE mathematically.

For those of you that are like me, some explanation might be helpful. Volumetric efficiency (in reference to gas engines) is a measure of how well an engine can move air and fuel in and out of the cylinders. It is expressed as a ratio or percentage volume of fuel and air actually admitted into the engine compared to the piston displacement volume. Thinking of an engine as an air pump, the greater power is produced by pumping more air and fuel through the engine/unit time (ie increasing VE).

Typical auto engines run VEs of 85-90%. DOHC, multiple valve/cylinder engines can have VEs above 100% up to 130%. Forced induction engines, like ours, can have VEs approaching 300%.

One point I would add to Dave's plot is that VE in a turbo engine is affected by more factors than just turbo choice. The engine's efficiency is affected by ease of getting air/fuel into and out of the engine ie intake, fuel system, and exhaust flow. Thus, I believe, the above differences in VE probably involve more than just efficiency of A28s vs. modded VTGs.

If you have any questions, ask Dave!!

I just like fiddling around with equations and couldn't have described VE any better than what you just said. I certainly didn't invent any thing here that isn't already known. One disclaimer-- I can't claim to be an expert by any means but I figure if I threw something out there that wasn't right then a true expert would correct me.

I just like fiddling around with equations and couldn't have described VE any better than what you just said. I certainly didn't invent any thing here that isn't already known. One disclaimer-- I can't claim to be an expert by any means but I figure if I threw something out there that wasn't right then a true expert would correct me.

I believe the compressor is 63.5 with clipped turbine. As you know, when I first started this modding business, I was truly clueless but since a significant amount of my income was going into my car, I figured I better educate myself.

Dave's going deep into comparing these turbos. + rep for doing the math! This is the data that many members are looking for when one tuner tells us how much better their turbos are.  Better info than a dyno, which fails to show boost threshold and other parameters.

Better info than a dyno, which fails to show boost threshold and other parameters.

Dave, do you have an easier way to calculate this? My understanding is 3 parameters need to be logged from the sensors:

Engine speed, MAF rate, and IAT.

Better info than a dyno, which fails to show boost threshold and other parameters.

Better info than a dyno, which fails to show boost threshold and other parameters.Dave, do you have an easier way to calculate this? My understanding is 3 parameters need to be logged from the sensors:

Engine speed, MAF rate, and IAT.

Last edited by TTdude; 01-01-2011 at 02:38 PM.

#11

VE Spreadsheet

Well, I tried to upload the spreadsheet but evidently Excel is not a file type that is acceptable for uploading.  So if you want me to send you the spreadsheet just email me at ttdude997@gmail.com.

So if you want me to send you the spreadsheet just email me at ttdude997@gmail.com.

All one has to do is to input RPM, MAF, and IAT from your datalog. It does not necessarily have to be from Durametric although the spreadsheet is designed to use metric units which Durametric records. Use the plotting function in Excel to generate your graph. This calculation assumes air density at sea level and 3.6L engine. A little tweaking of the density parameter would be necessary if you're running in the mountains or displacement for stroked engine. Peak VE would correspond to peak torque. This is like a "poor man's" dyno. Have fun.

So if you want me to send you the spreadsheet just email me at ttdude997@gmail.com.

So if you want me to send you the spreadsheet just email me at ttdude997@gmail.com. All one has to do is to input RPM, MAF, and IAT from your datalog. It does not necessarily have to be from Durametric although the spreadsheet is designed to use metric units which Durametric records. Use the plotting function in Excel to generate your graph. This calculation assumes air density at sea level and 3.6L engine. A little tweaking of the density parameter would be necessary if you're running in the mountains or displacement for stroked engine. Peak VE would correspond to peak torque. This is like a "poor man's" dyno. Have fun.

Last edited by TTdude; 01-01-2011 at 02:41 PM.

#14

Have you done any 60-130's or any other performance testing? I am looking into 20g's and was looking for baseline info. I realize you are a Tip, but it would be close enough.

#15

Here are some testing figures.

New record at Bruntingthorpe (20/11/2010)

0-100 in 6.27 secs (1.5 bar)

0-138.9mph in 10.82 secs 1/4 mile. (1.5bar)

Current Performance times (Vbox verified at Bruntingthorpe 14/10/2010)

Speed v Time (1.3bar)

0-60 3.2

0-100 6.6

0-150 13.7

0-160 15.8

0-170 18.4

0-180 21.8

0-186 24.0

0-200 30.8

0-200 unverified (no SD card but photo) of 29.8

In terms of speed v distance (1.3bar)

1/4 mile 135mph

1/2 mile 165mph

3/4 mile 182mph

1 mile 192mph

1.19miles 200mph

Other verified vbox runs.

0-60mph 3.3sec @ 1.3bar

0-100mph 6.6sec @ 1.3bar

0-130mph 10.48sec @ 1.3bar

60-100mph 2.67 sec @ 1.5bar

60-100mph 3.05 sec @ 1.3bar

0-150mph 14.3sec @ 1.3bar

0-150mph 13.89sec @ 1.41bar

60-130mph 6.66 @ 1.3bar

1/4 mile @ 10.81 @ 135.3mph

I just haven't had a real chance at 1.5 bar with good conditions and I haven't done a dedicated 60-130 run for a long time. Will do so in the next month.

Last edited by 996ttalot; 01-01-2011 at 03:40 PM. Reason: To correct bar.