Which upgrade with k16 turbos

#46

I'm guessing the cheap eBay billet wheels are direct copies of the oem cast wheels, therefore, no difference or gains. Whereas our tuners custom billet wheels likely have been tweaked a little bit in design for the extra gains.

#47

exactly, that makes sense. ok, well that goes along way toward explaining why there IS so little disparity between the two depicted in that graph. or does it. so then if you would explain the terminology for me?

a stock oem k16 "wheel" is "cast" while a billet 16 "wheel" is referred to as a "16"G". and the difference is?.. simply the material? or is there more in the 16g billet wheel, e.g. porting/polishing/backplating etc?

if the "wheel" is the same size, and the only differenitial being the material ( cast vs billet ) then wouldn't that be the way to conclusively determine which one is capable of making "more" power under equal conditions? again, wouldn't an "all else being equal" situation be necessary, and is that not what they compared? i'm not certain i'll ever truly understand this "difference". but thx for explaining.

a stock oem k16 "wheel" is "cast" while a billet 16 "wheel" is referred to as a "16"G". and the difference is?.. simply the material? or is there more in the 16g billet wheel, e.g. porting/polishing/backplating etc?

if the "wheel" is the same size, and the only differenitial being the material ( cast vs billet ) then wouldn't that be the way to conclusively determine which one is capable of making "more" power under equal conditions? again, wouldn't an "all else being equal" situation be necessary, and is that not what they compared? i'm not certain i'll ever truly understand this "difference". but thx for explaining.

Billet k16 though means nothing, all it means is you have a billet comp wheel, you need to know the size to really know the potential.

I've built hundreds of turbos and it's something I enjoy doing. Lots of ways to improve very turbo.

#49

This is not exactly true. Most of them are better higher flow design. They are usually taller, have extended tips and have a slightly more efficient fin design. Most are made in Taiwan which is why they are cheaper. Taiwan quality is super high though can I have all my billet wheels made there now. They are better both in quality and price compared to being made in the USA 95% of the time.

#50

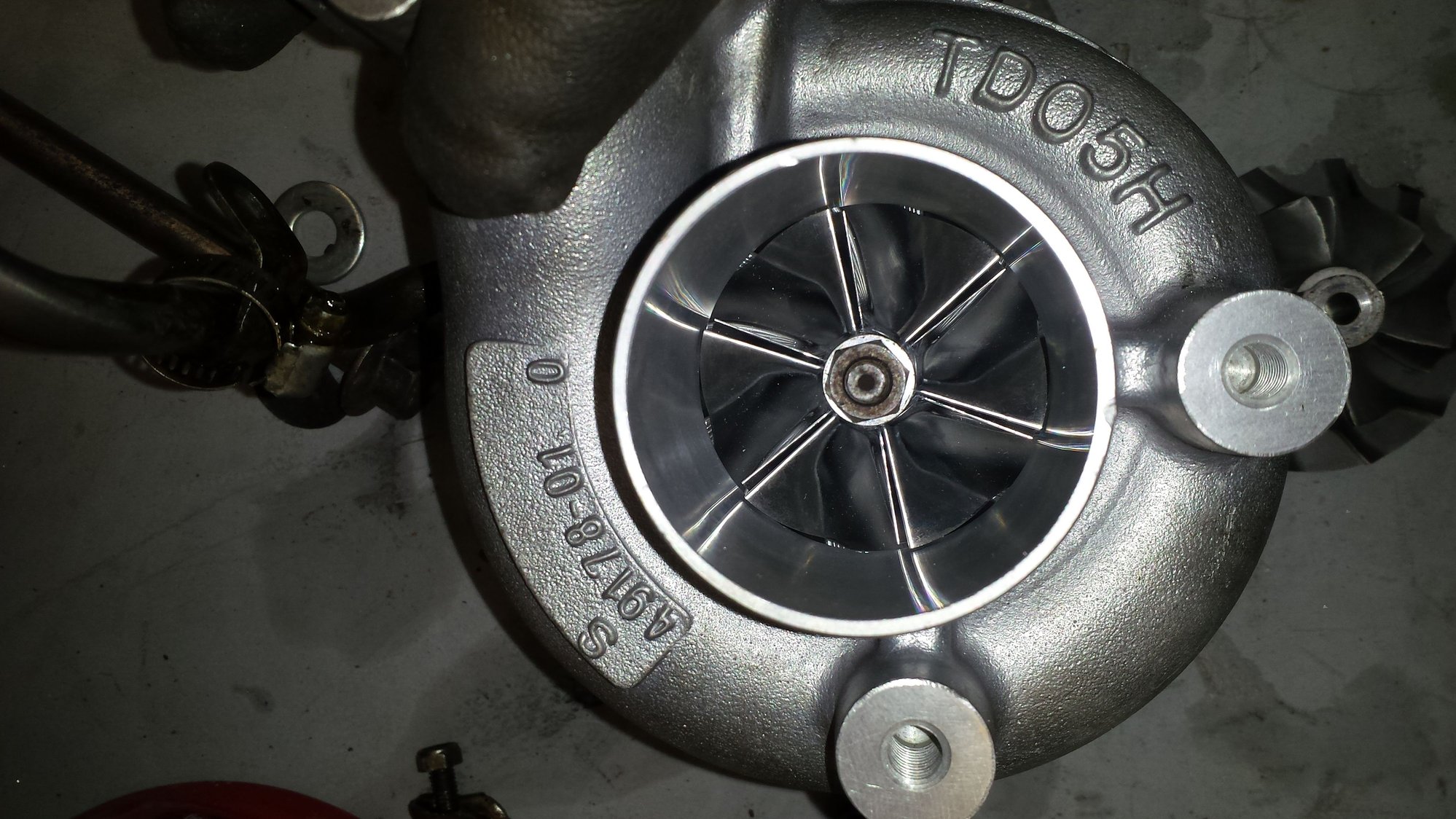

flewis763...cool pics. Makes it easy to see the size difference of the wheels.

Yeah, ultimately just billet vs cast is not going to make too much difference in performance it's the design/size/etc of the wheels.

Yeah, ultimately just billet vs cast is not going to make too much difference in performance it's the design/size/etc of the wheels.

#51

Originally Posted by flewis763

This is not exactly true. Most of them are better higher flow design. They are usually taller, have extended tips and have a slightly more efficient fin design. Most are made in Taiwan which is why they are cheaper. Taiwan quality is super high though can I have all my billet wheels made there now. They are better both in quality and price compared to being made in the USA 95% of the time.

#52

The stock k16 wheel and a 16g wheel are much different. A k16 wheel is 40.5/60.5mm wheel. A 16g is 48.5/68mm wheel. Basically it's 8mm larger both inducer and exduce which a huge difference.

Billet k16 though means nothing, all it means is you have a billet comp wheel, you need to know the size to really know the potential.

I've built hundreds of turbos and it's something I enjoy doing. Lots of ways to improve very turbo.

Billet k16 though means nothing, all it means is you have a billet comp wheel, you need to know the size to really know the potential.

I've built hundreds of turbos and it's something I enjoy doing. Lots of ways to improve very turbo.

now THAT i understand. thanks. last question ( if i may ?) the "clipping" of the wheel whether cast or billet ( though the billet wheel may be the only one that can be "clipped" ) does what exactly? allow for a quicker spool? or is "lighter" and spins more freely? or is that way off base?

#53

now THAT i understand. thanks. last question ( if i may ?) the "clipping" of the wheel whether cast or billet ( though the billet wheel may be the only one that can be "clipped" ) does what exactly? allow for a quicker spool? or is "lighter" and spins more freely? or is that way off base?

Clipping a turbine allows the exhaust gasses to exit the turbine wheel faster. This increases flow but also slows spool. It's a cheap and easy way to increase overall flow without machine the housing and putting a larger wheel in. I'll see if I can find a pic here.

#55

Clipping is on the turbine wheel not the compressor. A clip is when the exducer of the turbine is machined back at and angle. 5, 7.5, and 10 degree are the most common clips but I have seen guys go all the way to 20 degrees before.

Clipping a turbine allows the exhaust gasses to exit the turbine wheel faster. This increases flow but also slows spool. It's a cheap and easy way to increase overall flow without machine the housing and putting a larger wheel in. I'll see if I can find a pic here.

Clipping a turbine allows the exhaust gasses to exit the turbine wheel faster. This increases flow but also slows spool. It's a cheap and easy way to increase overall flow without machine the housing and putting a larger wheel in. I'll see if I can find a pic here.

finally, a "turbos for dummies" few paragraphs that i understand and am enlightened. appreciate it! cobb had some garret pic/graphs that helped also.

appreciate the explanation(s).

Last edited by '02996ttx50; 12-15-2015 at 03:00 PM. Reason: clarity

Thread

Thread Starter

Forum

Replies

Last Post