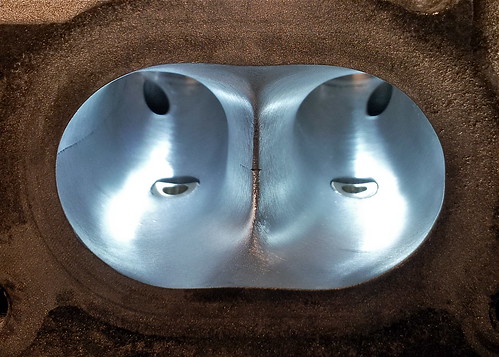

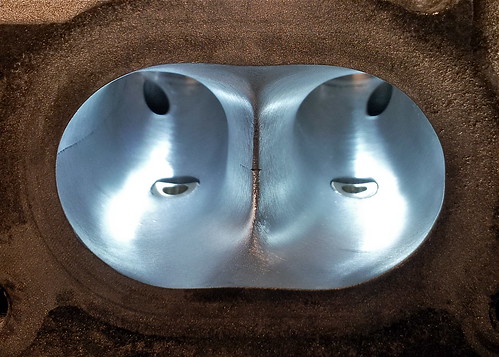

Doing some light porting to my heads.

#1

Doing some light porting to my heads.

I decided to clean up my heads before I do my build. I'm not really taking off a ton of material so I'm not expecting huge results, but it should help some. Some of the transitions in the bowl/seat area were pretty bad. I was able to match them up nicely. I did take off some around the edges of the intake port and am matching the intake pipes to them as well. I shaved down the center section on the exhaust ports and finished them with 120 grit. The intakes are finished with 80 grit. I will polish the combustion chamber next and I think I will port my turbos as well.

#2

You may feel a difference! I've ported for decades and have found the initial shaping and removal of obvious obstructions that would cause unwanted eddies will make the most difference. The time consuming and final finish or polishing as we did 25-40 years ago took the most time. Looking back, the shiny and mirror finish was more about justification of the cost and to "wow" the owner and assure the placebo effect. Way back, we didn't know a mirror finish was not the best. I've never had or used a flow bench but have seen results on a race track. In my opinion dynos and flow benches can be great tools, but often experience trumps computer generated graphs obtained from running your vehicle on a roller.

#4

I did some research and 80 is what I came up with. It's much smoother than the stock casting at least. On a budget so nothing too fancy here.

#5

I'd at least check on coatings, there used to be some that were water based and could be applied with a sponge brush. I'll poke around and see what I can find, are the heads disassembled? Supposedly the turbo heads have pretty rough casting from the factory

Edit: duh obviously disassembled! Here's the stuff I was thinking of, haven't used it but it's been around for ages. Must be baked on in an oven blah blah

http://www.techlinecoatings.com/hi-p...-coatings.html

Edit: duh obviously disassembled! Here's the stuff I was thinking of, haven't used it but it's been around for ages. Must be baked on in an oven blah blah

http://www.techlinecoatings.com/hi-p...-coatings.html

Last edited by BLKMGK; 06-30-2016 at 07:23 PM.

#6

Yes 60 or 80 is what you want to finish the intake side with. Exhausr I go to 240 and finish with a crossbuff.

#7

Trending Topics

#8

Allright, I will get the exhaust side really smooth. Progress is on hold, I need a 6 inch burr to reach inside the intakes to match the ports.

#9

Heads are coming along nicely. I bought a nice set of carbide burrs with long shanks so I could reach in there. I took a ton of material off of the bolt on intake runners to match them to the heads. I am still doing some smoothing but it looks good.

#10

Don't over do it or your bottom end may suffer. Velocity is important, more so than maximum flow at low throttle demands.

Let us know your results when the car is back together, either with dyno or better, seat of the pants.

Let us know your results when the car is back together, either with dyno or better, seat of the pants.

#11

I think the heads are designed to be ported. On the intake side there is a tapered gap cast inbetween the head and the intake runner and the gasket surrounds the outside of the gap. You shave the gap out and clean up the transitions and the flow looks perfectly balanced like it is supposed to be that way.

#12

I am going to have these put on a flow bench. They are turning out really well. I think pwdrhound has posted up some before and after numbers for his heads in a few threads that we can compare with.

#14

It is just the picture. I don't dare touch the splitter or anything that I probably can not replicate for each port. I am careful to not go beyond my skill level. I think most of the gains will come from improving the transition between the valve seat and the aluminum. Smoothing out the casting and opening the ports a bit should contribute a little. I am using stock valves and springs.

#15

I'm pretty handy but this is a project I left to the pros. Todd McKenzie ported and flowed my head. He's been doing this for several decades. He also installed his high RPM valve train. I felt this was money well spent and reasonable.

Note how the stock intake manifold does not properly match up with the head. Todd went the extra step by match porting the intake manifold to the head for a seamless transition. Many ignore this extra step. You can also see how much thinner the intake manifold wall is after his port work as he opened it up to funnel more air directly to the head.

Anyone considering getting some Porsche headwork done, I would highly highly recommend Todd McKenzie. Turnaround time including shipping was a little over 2 weeks and I told Todd there is no need to rush it as I was out of town anyway. Todd said he can normally turn it in 1 week or so. I think the numbers speak for themselves. The % improvement over stock for both the intake and exhaust side is calculated in 0.050" increments and shown in the two columns on the far right. You can see a huge improvement in flow with an average intake improvement of 78.5% (27%min-120%max) and an average exhaust improvement of 68.7% (26%min-120%max). Keep in mind, valves are stock OEM size as we decided to stick with those as opposed to going bigger. Todd added his own springs, guides, etc..

[url=https://flic.kr/p/rrzTDr]

Stock intake port

[url=https://flic.kr/p/qmbSh5]

Todd McKenzie intake port

[url=https://flic.kr/p/qYRcon]

Stock exhaust Port

[url=https://flic.kr/p/ri4ABP]

Todd McKenzie exhaust port

[url=https://flic.kr/p/rfSqQ3]

[url=https://flic.kr/p/rrNyhL]

[url=https://flic.kr/p/rpB2bf]

[url=https://flic.kr/p/rajw7S]

[url=https://flic.kr/p/rrMisr]

Note how the stock intake manifold does not properly match up with the head. Todd went the extra step by match porting the intake manifold to the head for a seamless transition. Many ignore this extra step. You can also see how much thinner the intake manifold wall is after his port work as he opened it up to funnel more air directly to the head.

Anyone considering getting some Porsche headwork done, I would highly highly recommend Todd McKenzie. Turnaround time including shipping was a little over 2 weeks and I told Todd there is no need to rush it as I was out of town anyway. Todd said he can normally turn it in 1 week or so. I think the numbers speak for themselves. The % improvement over stock for both the intake and exhaust side is calculated in 0.050" increments and shown in the two columns on the far right. You can see a huge improvement in flow with an average intake improvement of 78.5% (27%min-120%max) and an average exhaust improvement of 68.7% (26%min-120%max). Keep in mind, valves are stock OEM size as we decided to stick with those as opposed to going bigger. Todd added his own springs, guides, etc..

[url=https://flic.kr/p/rrzTDr]

Stock intake port

[url=https://flic.kr/p/qmbSh5]

Todd McKenzie intake port

[url=https://flic.kr/p/qYRcon]

Stock exhaust Port

[url=https://flic.kr/p/ri4ABP]

Todd McKenzie exhaust port

[url=https://flic.kr/p/rfSqQ3]

[url=https://flic.kr/p/rrNyhL]

[url=https://flic.kr/p/rpB2bf]

[url=https://flic.kr/p/rajw7S]

[url=https://flic.kr/p/rrMisr]