Ceramic Coating on headers...

#16

IS header ceramic coating something you can do yourself. A dude in our local PCA is buying a system http://www.columbiacoatings.com/ for doing this kida thing. I asked if it can do ceramic and he replied: "Yes you can do ceramic thats what I am getting it primarily for.... I am going to coat the headers and crossover pipe.... I also have my engine apart so I will be coating the camshaft housings (and a few other pieces), and clear powder coating my intake manifold. I will polish the intake and then cook it."

Any input on this?

Mike

Any input on this?

Mike

#18

Kevin did a kick *** job on mine

So good in fact that during the shoot out after 5-6 Cort Wagner laps and more... Kevin and I could touch them with our bare hands... When I used to adjust my waste gates with my stock headers, it would take at least 15-20 minutes of cool down before I could get anywhere near them...

So good in fact that during the shoot out after 5-6 Cort Wagner laps and more... Kevin and I could touch them with our bare hands... When I used to adjust my waste gates with my stock headers, it would take at least 15-20 minutes of cool down before I could get anywhere near them...

#20

Would it be better to get a set of Ahrky's headers or to get a set of 4GT headers and polish and ceramic coat those??

I need headers ASAP but have had no luck in finding a set of stockers for a reasonable price (I want to do Sharky's ones unless someone here chimes in otherwise and wanted to keep my stockers)

I need headers ASAP but have had no luck in finding a set of stockers for a reasonable price (I want to do Sharky's ones unless someone here chimes in otherwise and wanted to keep my stockers)

#22

LOL Kevin....Finally you chipped in...I am wondering if porting and coating a set of stockers woul be better than ding the same to a set of 4GT headers to go with your turbos?? You can e-mail me if you do not wish to make this public

#23

I am not experienced about headers, but I think it depends

on where you want your power. For max-power at max revs

at full-on wide open throttle, it may be good to have one of the

aftermarket bigger-pipe headers, but for real-world lack-of-lag

you (I) probably want the shortest, most insulated pipes as

long as they are not needlessly inefficient. For me, they would

be stock headers, ported to match the head and make the

transition to the pipe as smooth as possible. I would consider

a durable coating on the outside, that kept the heat in, but

I would be queasy about an internal coat unless it came with

a guarantee that the coater would pay for new turbos if it

came off and the turbos were damaged in the least...

It sounds like Porsche PHD is my man, and the next time my

car is in the shop I'll see about a swap.

I know that S Car Go has made several iterations of after-

market headers, and they are beautiful to behold, but I have

heard only cases that they didn't help power, and the last I

heard was that they were going to make some short, narrow

pipe headers to try to help a stockish car get power. I had asked

for dyno proof that they worked, but it never came. I think

Porsche did *very well* with the design of the stock headers...

Joe Weinstein

on where you want your power. For max-power at max revs

at full-on wide open throttle, it may be good to have one of the

aftermarket bigger-pipe headers, but for real-world lack-of-lag

you (I) probably want the shortest, most insulated pipes as

long as they are not needlessly inefficient. For me, they would

be stock headers, ported to match the head and make the

transition to the pipe as smooth as possible. I would consider

a durable coating on the outside, that kept the heat in, but

I would be queasy about an internal coat unless it came with

a guarantee that the coater would pay for new turbos if it

came off and the turbos were damaged in the least...

It sounds like Porsche PHD is my man, and the next time my

car is in the shop I'll see about a swap.

I know that S Car Go has made several iterations of after-

market headers, and they are beautiful to behold, but I have

heard only cases that they didn't help power, and the last I

heard was that they were going to make some short, narrow

pipe headers to try to help a stockish car get power. I had asked

for dyno proof that they worked, but it never came. I think

Porsche did *very well* with the design of the stock headers...

Joe Weinstein

#25

Kevin:

regarding to the headers for exchage. Are they the Evo header with ceramic coating? or just stock header?

b/c I personally have the evo, and would like to have it exchanged to evo header as well...not stock ones though....

regarding to the headers for exchage. Are they the Evo header with ceramic coating? or just stock header?

b/c I personally have the evo, and would like to have it exchanged to evo header as well...not stock ones though....

#26

Mansour:

if you have heard anythign from Kevin, please also forward it to me as well ^_^

luting_chen@hotmail.com

I personally prefer Evo coated header, but dont know if that's the piece they have in stock for exchange. b/c with the exchange price quoted, I can get almost get a new set of evo header... so i hope it better not be stock...

if you have heard anythign from Kevin, please also forward it to me as well ^_^

luting_chen@hotmail.com

I personally prefer Evo coated header, but dont know if that's the piece they have in stock for exchange. b/c with the exchange price quoted, I can get almost get a new set of evo header... so i hope it better not be stock...

#28

still deciding of which one to go for...^_^

written both of them email... and i'll see what's up afterward...

Chad:

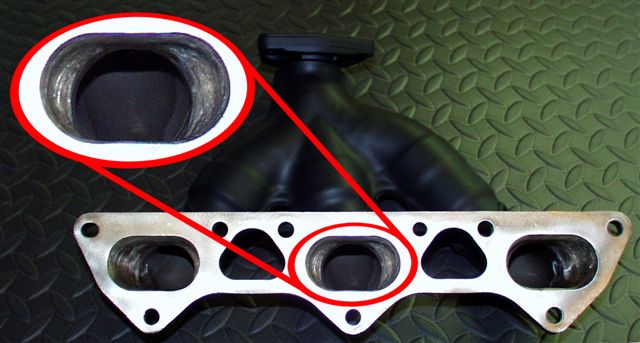

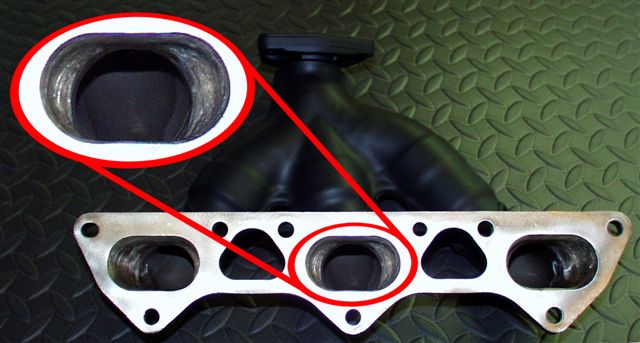

I have one thing in concern, if you ceramic coated your header, are you still able to install the EGT sensor there? b/c I know that it requires drilling a hole on the header. And I wonder if this will crack the internal ceramic coating of the header, thus flake and damage the turbo. (I think the company you provided coated the header inside out)

Is it an issue to you? or you have some other way to go around it?

b/c cost wise I prefer your method. it's much cheaper than labor intensed polishing job. but I'll see what's going on later...

written both of them email... and i'll see what's up afterward...

Chad:

I have one thing in concern, if you ceramic coated your header, are you still able to install the EGT sensor there? b/c I know that it requires drilling a hole on the header. And I wonder if this will crack the internal ceramic coating of the header, thus flake and damage the turbo. (I think the company you provided coated the header inside out)

Is it an issue to you? or you have some other way to go around it?

b/c cost wise I prefer your method. it's much cheaper than labor intensed polishing job. but I'll see what's going on later...

#29

why dont u tried to extrude hone it in the inside and have the outside cermaic coated, when you drill the hole for the EGT luting it is advisable to do it while the header is out of the car to reduce the chances of getting shavings into your brand new turbo..

i believe that extrude hone is better than polishing, bec.. it gets into evry crevise, bend etc. of the header, while polishing, i sonly where the machine can reach it...

extrude honing is a process where theypush an abrasive putty through the material which smoothens out the surface...

http://www.extrudehone.com/powerflow.html

sorry if i am giving you too much ideas...

i believe that extrude hone is better than polishing, bec.. it gets into evry crevise, bend etc. of the header, while polishing, i sonly where the machine can reach it...

extrude honing is a process where theypush an abrasive putty through the material which smoothens out the surface...

http://www.extrudehone.com/powerflow.html

sorry if i am giving you too much ideas...

#30

Joe...wow...this is some interesting stuff....

I don't think many people have done it on this board...

hm... maybe I should do it? hahaha... and see how it goes...

yeah, I'll be taking out the header for installing egt for sure...

but what I was talking about is something like this...

if you paint your desk with a thick layer of paint (in this case ceramic), and then drill a hole from the bottom of your desk... after the drilling is done, the surface paint may crack a bit... thus from then on... the peeling start to happen. like you can dig away some paint on ur desk with ur nail by scratching it... since it's cracked already...

I don't know if this applies to ceramic...may be I'm a bit too concerned...

I don't think many people have done it on this board...

hm... maybe I should do it? hahaha... and see how it goes...

yeah, I'll be taking out the header for installing egt for sure...

but what I was talking about is something like this...

if you paint your desk with a thick layer of paint (in this case ceramic), and then drill a hole from the bottom of your desk... after the drilling is done, the surface paint may crack a bit... thus from then on... the peeling start to happen. like you can dig away some paint on ur desk with ur nail by scratching it... since it's cracked already...

I don't know if this applies to ceramic...may be I'm a bit too concerned...