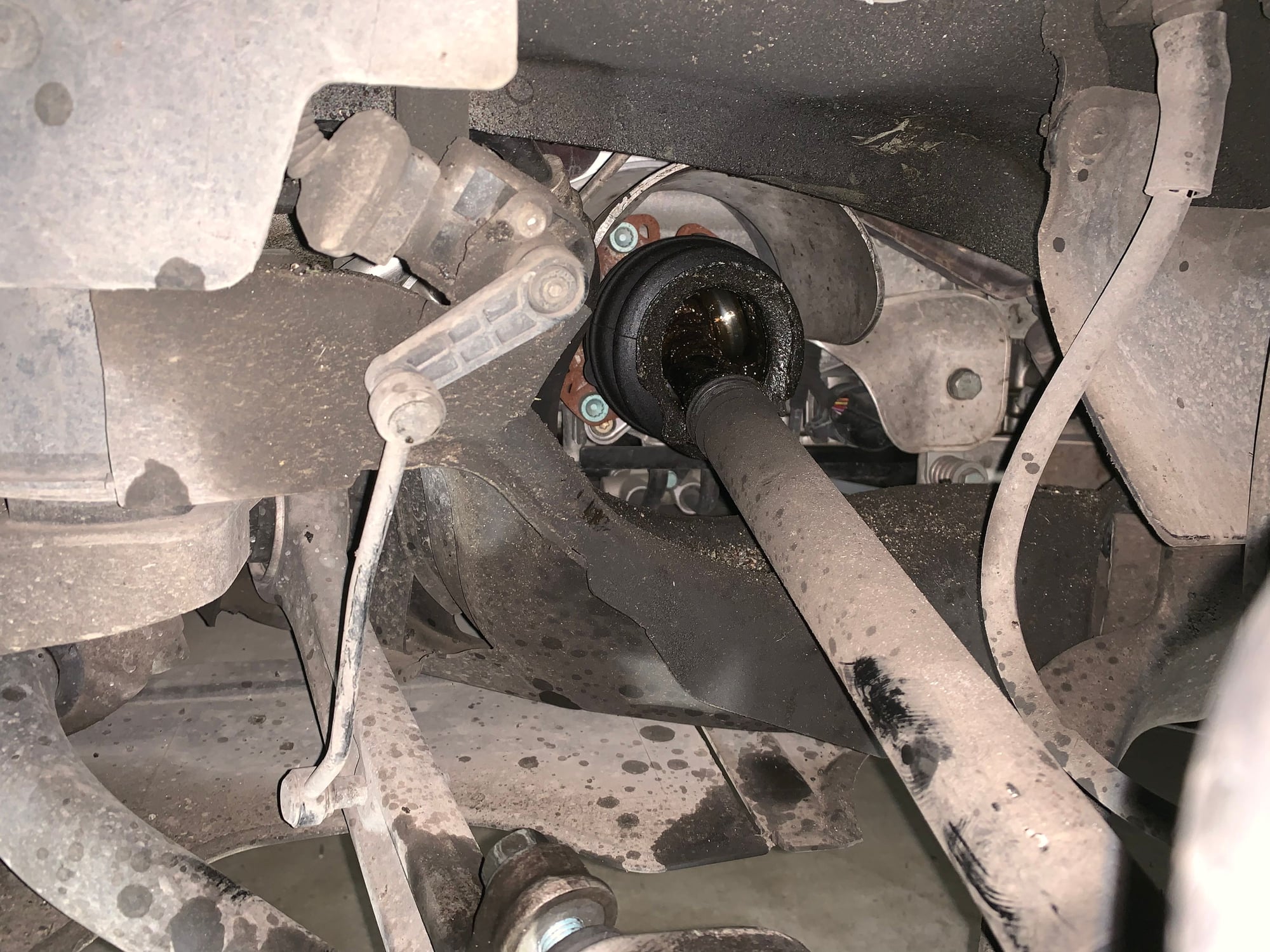

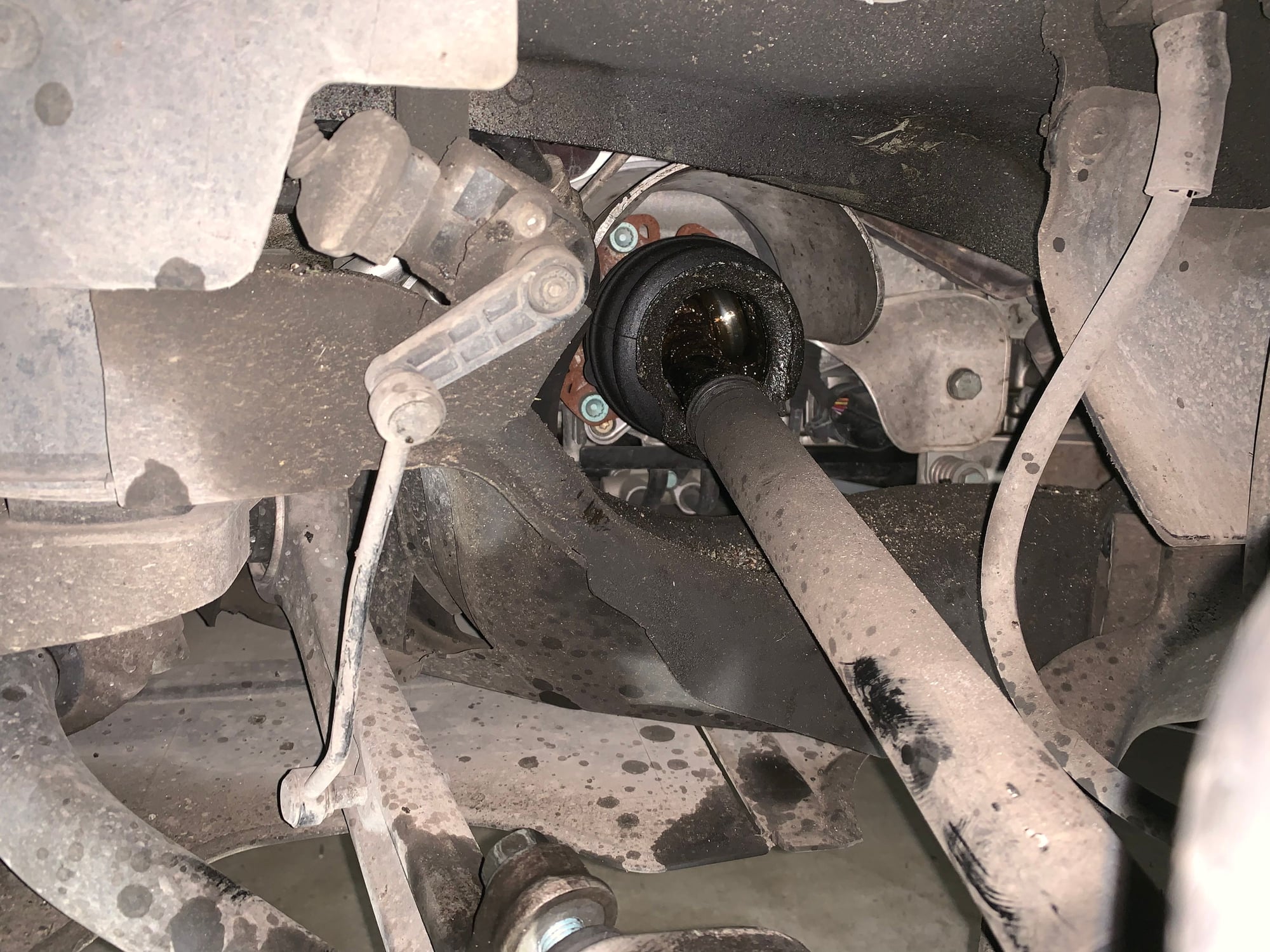

Need new CV axle

#1

Need new CV axle

#2

EA

Ok time to replace my bad CV boot.

First, I removed the air shock and disconnected the upper suspension linkages. Decided to take the easy way out and not disconnecting the outer spline of the shaft.

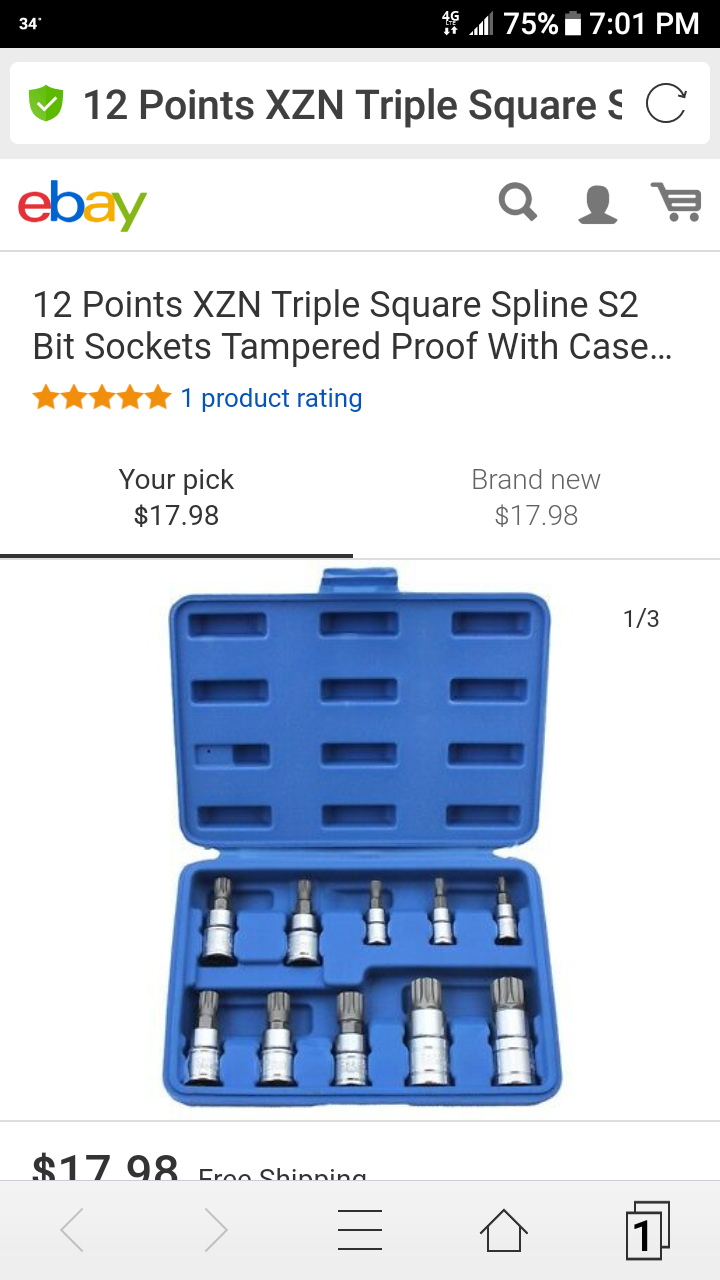

Yes, you do require a special tool to remove the inner mount, called a 10mm double box bit. This is not a torx. If you try using a torx rather than a double box, you will strip the bolt. I used an impact wrench to unbolt the mount, making it really easy.

Use a hammer to knock out the casing from the rollers.

Remove the spring clip and then the rollers

Remove the outer spring clip (the thicker clip), then the rest the CV boot. Clean everything really good afterwards.

Note: the rollers has two different sides. Here a picture of the beveled side. This side faces outward toward the wheels when installed again

Here is a picture of the flat inner side.

Install the new boot, big spring clip and use a socket like this to tap the rollers back into place, far enough so you can install the inner spring clip

Smother the rollers with CV grease and fill the casing and boot with the rest of the CV joint grease supplied in the kit. Then install and tighten the clips on the boot and you are done. Easy Job when you have all the right tools

I found this post from the past of (Mr. Zaos),which is very informative. Hope it helps.

The axle shafts of the non-turbo W12's is a smaller diameter than the W12 turbocharged axle shafts in the Bentley, at least that was my conclusion after research.

Last edited by 1eapplebaum; 02-24-2019 at 06:19 PM.

#4

When performing the CV shaft project, a frustrating part was the bolts holding the CV axle onto the output of the transmission must have had factory applied high-strength Loctite. Had to heat each bolt. Doing this project with the engine in is tight.

Wear rubber gloves, CV grease is nasty.

Wear rubber gloves, CV grease is nasty.

#5

Thanks again.

Do you know what exactly is this 10mm double box bit/socket thing is? Iím trying to order one but keep coming up with wrenches.

He wouldnít be talking about a XZN M10? But in a impact?

Do you know what exactly is this 10mm double box bit/socket thing is? Iím trying to order one but keep coming up with wrenches.

He wouldnít be talking about a XZN M10? But in a impact?

Last edited by TeamJones1962; 02-24-2019 at 07:33 PM.

#7

Trending Topics

#9

I just replaced my driver's side front axle with a RMT after finding my boot torn while doing the RMT shocks.struts. I have my axle if you're interested in it, I could ship it to you and you could do the boot replacement if you didn't want to buy a completely new one. I got my triple square bits at my local oreilly's. You'll also need a giant allen bit/socket to break the axle/hub bolt loose.

#10

With respect to all FYI.

When doing the driver side CV axle, bought the RMT replacement unit. At least my experience, received a smaller diameter shaft then the OEM Bentley Continental GT. Researching this, discovered that for example, Audi A8 Quattro W12 uses this replacement cv axle shaft. The unit will bolt up to the Bentley. Sent the axle shaft back to RMT.

As noted earlier my impression is the non turbo W12's use the smaller front axle shaft. The Bentley produces more horsepower and torque and it is likely the engineers beefed up the front CV axle shafts.

Ended up rebuilding mine. Wasn't too difficult.

Another tool to complete axle shaft rebuild is the crimping tool for the cv boots. This is the same tool used for the oiniker clamps found throughout the vehicle. Car part stores have the tool.

When doing the driver side CV axle, bought the RMT replacement unit. At least my experience, received a smaller diameter shaft then the OEM Bentley Continental GT. Researching this, discovered that for example, Audi A8 Quattro W12 uses this replacement cv axle shaft. The unit will bolt up to the Bentley. Sent the axle shaft back to RMT.

As noted earlier my impression is the non turbo W12's use the smaller front axle shaft. The Bentley produces more horsepower and torque and it is likely the engineers beefed up the front CV axle shafts.

Ended up rebuilding mine. Wasn't too difficult.

Another tool to complete axle shaft rebuild is the crimping tool for the cv boots. This is the same tool used for the oiniker clamps found throughout the vehicle. Car part stores have the tool.

#11

Dave01gt, I bought the RMT ones already, should be here Wednesday. Im going to see if mines can be fixed with the kit and if so send the RMTís back. Iím more electrical incline then mechanical so I want things to be as easy as possible. Thanks for all the info guys.

1eapplebaum, when did you do yours? Iím trying to get this done ASAP as the wife is giving me the side eye for taking up the garage lol.

1eapplebaum, when did you do yours? Iím trying to get this done ASAP as the wife is giving me the side eye for taking up the garage lol.

Last edited by TeamJones1962; 02-25-2019 at 07:06 PM.

#12

About a year ago. Rebuilding the axle shafts was the easier part of the job. The removal and installation takes more time.

There is the possibility of having to do a front end alignment as well. At the top of the steering linkage there's one component with about a quarter inch gap. Measure it before removeing it. That's an important aspect of keeping the alignment true.

The axle shafts are good if there is no torsional movement. To test this with the vehicle on the ground by hand turn the axle shaft both directions and see if you can feel a wiggle. Then lift up and down. No looseness then it is rebuildable.

Research the Audi A8 Quattro W12 or the Volkswagen Phaeton W12 front axle boot repair kits they should work. Since the shaft is larger on the Bentley they might be somewhat snug to slide up the shaft, use wd40.

There is the possibility of having to do a front end alignment as well. At the top of the steering linkage there's one component with about a quarter inch gap. Measure it before removeing it. That's an important aspect of keeping the alignment true.

The axle shafts are good if there is no torsional movement. To test this with the vehicle on the ground by hand turn the axle shaft both directions and see if you can feel a wiggle. Then lift up and down. No looseness then it is rebuildable.

Research the Audi A8 Quattro W12 or the Volkswagen Phaeton W12 front axle boot repair kits they should work. Since the shaft is larger on the Bentley they might be somewhat snug to slide up the shaft, use wd40.

Last edited by 1eapplebaum; 03-02-2019 at 07:05 AM.

#13

I bought struts from RMT for my 08 GT Speed. I was given the parts for non-Speed model and had a really hard time returning them.

Lucky for me I had email communications and purchased via PayPal so they were able to refund me but did have to report it to PayPal for that to happen.

Honestly was super displeased with RMT trying to sell parts as oem replacements that arenít actually oem replacements.

Lucky for me I had email communications and purchased via PayPal so they were able to refund me but did have to report it to PayPal for that to happen.

Honestly was super displeased with RMT trying to sell parts as oem replacements that arenít actually oem replacements.

#14

I think you've used the wrong jaws on your caliper to measure the diameter looking at your picture! You need to use the jaws which are parallel with each other, from the picture you've used the jaws for measuring internal spaces.

#15

Damn, your right!!! In a rush on my way to work when I did it. Iíll correct it today. Thanks for the correction.