Replacement Vertex Center Driveshaft Support Bearing Bushing [PICS] [VIDEO]

#1

If you read my recent autocross thread, then you would know that I just ruined a good OEM center driveshaft support bearing bushing in just one day of track use. I repeat, one single day. Even though I probably could have had it replaced under warranty, I wanted to look for a more permanent solution.

I have known about the Vertex Auto replacement center driveshaft support bearing bushing (what a long name!) for about a year now and spoke to them over the phone around last May. They are extremely confident about this product, have a pending patent, where I was told they sell "hundreds" of them each month for the Touareg, Q7, and Cayenne crowd.

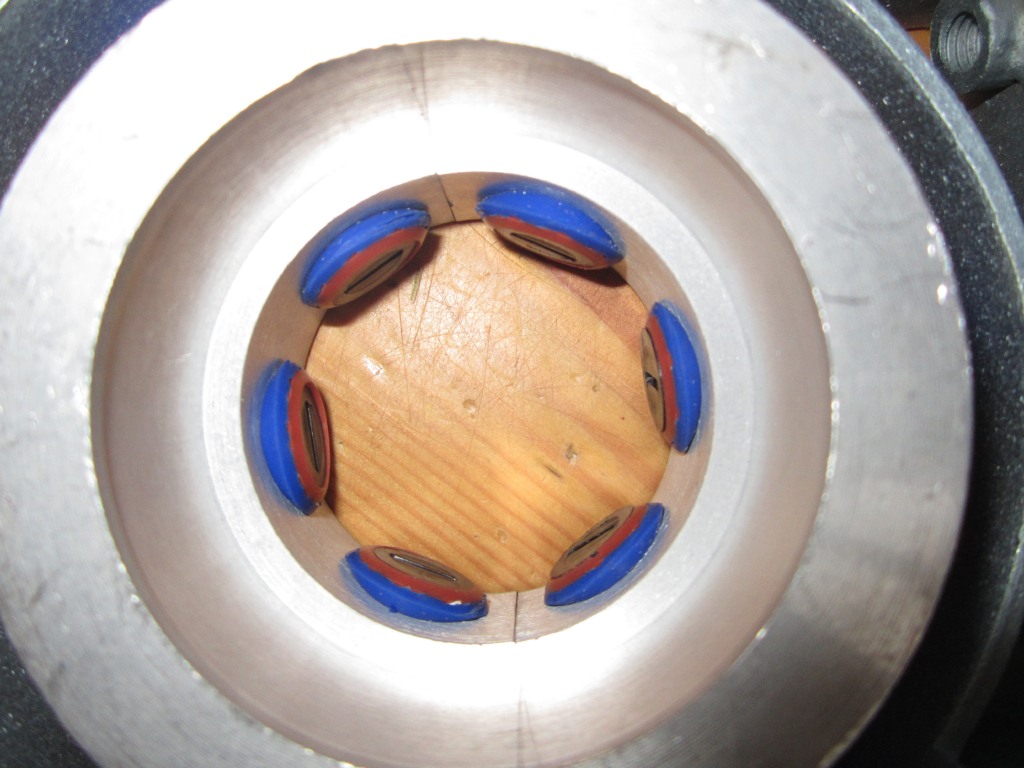

From an engineering perspective, the design looks solid whereas the internal section is CNC machined out of aluminum where it clamps around the existing DS bearing. I could not find any online complaints so I ordered this part and a replacement damper (flex disc). Additionally, the design is modular and allows you to install and remove the bushing without needing to drop the driveshaft and exhaust. So, it should prove easy to service, if need be, in the future. Moreover, they are also marketing that this is a permanent solution.

I installed it in about half a day and very happy with it so far. FWIW, I made sure to replace the mild steel allen screw that came with it, with stainless steel allen screws (M6 x 1.0) from the local hardware store and applied anti-seize to protect against corrosion. No more KNOCK KNOCK KNOCK KNOCK!. In fact, it seems better able to handle my higher levels of torque. When turning 90 deg. and applying WOT (cause fun, clearly ) the stock unit, even when brand new, would slightly knock until throttle lift. The vertex unit does not complain at all. All tire chirps and chassis flex.

) the stock unit, even when brand new, would slightly knock until throttle lift. The vertex unit does not complain at all. All tire chirps and chassis flex.

Here are pics of the unit itself and the install procedure:

I have known about the Vertex Auto replacement center driveshaft support bearing bushing (what a long name!) for about a year now and spoke to them over the phone around last May. They are extremely confident about this product, have a pending patent, where I was told they sell "hundreds" of them each month for the Touareg, Q7, and Cayenne crowd.

From an engineering perspective, the design looks solid whereas the internal section is CNC machined out of aluminum where it clamps around the existing DS bearing. I could not find any online complaints so I ordered this part and a replacement damper (flex disc). Additionally, the design is modular and allows you to install and remove the bushing without needing to drop the driveshaft and exhaust. So, it should prove easy to service, if need be, in the future. Moreover, they are also marketing that this is a permanent solution.

I installed it in about half a day and very happy with it so far. FWIW, I made sure to replace the mild steel allen screw that came with it, with stainless steel allen screws (M6 x 1.0) from the local hardware store and applied anti-seize to protect against corrosion. No more KNOCK KNOCK KNOCK KNOCK!. In fact, it seems better able to handle my higher levels of torque. When turning 90 deg. and applying WOT (cause fun, clearly

) the stock unit, even when brand new, would slightly knock until throttle lift. The vertex unit does not complain at all. All tire chirps and chassis flex.

) the stock unit, even when brand new, would slightly knock until throttle lift. The vertex unit does not complain at all. All tire chirps and chassis flex.Here are pics of the unit itself and the install procedure:

Last edited by Renaissance.Man; 04-19-2013 at 02:51 PM.

#3

After that, I used a flap disk to get it down to bare metal without gouging the outside of the bearing. Which was my biggest issue with the video, they gouge the crap out of the bearing with a right-angle die grinder / cutoff wheel combination.

#4

that video is a good reason to diy everything lol. I always have but that's another story. I heard about these about a week ago, when mine starts knocking it the route i will be taking as well.

definitely look forward to you making another trip to lime rock and reporting backi

definitely look forward to you making another trip to lime rock and reporting backi

Last edited by stormy69; 04-26-2013 at 10:41 PM.

#6

The $45 part wont last, thats the point. it is also much more difficult to install...

#7

$389 price-- Page 127 June 2013 EPS ad in Excellence Magazine--shows new price $389 orig price $549--"now available at Automotion and Pelican Parts".

Trending Topics

#9

I'm still not totally sold on these.

The Porsche factory part is know me to last about 60-120k for the early part numbers. No idea in the later versions?!

The question is "why does it fail"? Is the bearing itself starting to lock up causing the outer shell to spin and tear the rubber bushing? That appeared to be the case on mine at 90k miles.

This product doesn't replace the bearing only the torn bushing. So is it really fixing it?

Also, not all Cayennes have a driveshaft bushing fail. So how many millions of miles are being driven on the Porsche designed part vs how many miles do people with these "permanent fix" replacements *really* have on them????? Seriously! How many people had a newer revision Porsche part fail and now have 2-3x as many miles on this fix? Is it really a fix or just too soon to really know?

Also not any cheaper than buying a complete rebuilt shaft with new bearing.

The Porsche factory part is know me to last about 60-120k for the early part numbers. No idea in the later versions?!

The question is "why does it fail"? Is the bearing itself starting to lock up causing the outer shell to spin and tear the rubber bushing? That appeared to be the case on mine at 90k miles.

This product doesn't replace the bearing only the torn bushing. So is it really fixing it?

Also, not all Cayennes have a driveshaft bushing fail. So how many millions of miles are being driven on the Porsche designed part vs how many miles do people with these "permanent fix" replacements *really* have on them????? Seriously! How many people had a newer revision Porsche part fail and now have 2-3x as many miles on this fix? Is it really a fix or just too soon to really know?

Also not any cheaper than buying a complete rebuilt shaft with new bearing.

#10

One supposition is that the stock bearing support allows too much flex in bearing area in response to lateral forces, which in time results in bearing wear and/or failure. The EPS part seems intended to eliminate most of the potential flex resulting in far less stress on the bearing over time. If my cardan shaft goes again, I'd be inclined to install one of these along with the replacement shaft.

#11

from what i have seen, it is the bushing that fails 90 percent of the time. Why buy a new shaft if it just needs a bushing. yes, you could buy the replacement setup form ECS but know that it will fail all too soon. iirc, RM's only lasted 40k miles or so. Now, you could say, well he is making much more power than stock so that's why his is bad... but i have seen them in v6 toureg failed at ~ the same mileage.

#12

So this vertex replacement bushing only addresses the symptom and potentially not that actual cause.

To replace the bearing and have a rebuilt CV joint with fresh lube in between shaft sections. All wear items that should be addressed to repair and maintain ANY driveshaft on earth properly. Not to mention the whole drive shaft set up costs less than just this bushing set up

So this brings up two points.

First. The busing failure seems to effect all Cayennes/Touregs equally. So it doesn't seem to be a HP or performance driving related issue.

Secondly. How many of these vertex replacement bushings are out there with more miles of them than the stock set up? Any at at?

#13

That's a fair question. I'm under the impression that it is a fairly new product. If that's the case, then there probably is not much user experience to go on yet. Still seems like an interesting and likely useful product though.

#14

I'd of been all over "trying it" if it didn't cost more than a complete shaft. My first stock one lasted to 90k. So in theory I should get similar use out of the new one (updated part number too) vs trying a barely tested product (by comparison)

#15

One supposition is that the stock bearing support allows too much flex in bearing area in response to lateral forces, which in time results in bearing wear and/or failure. The EPS part seems intended to eliminate most of the potential flex resulting in far less stress on the bearing over time. If my cardan shaft goes again, I'd be inclined to install one of these along with the replacement shaft.

Considering that a company designed an aftermarket replacement to address the concerns of the stock design, means that a company saw enough issues in the field to warrant R&D, obtain a patent (not cheap), and possibly profit from these issues moving forward. From what I hear, which maybe exaggerated, they are having no issues selling these replacements on a daily basis. From my own knowledge, this product has been on the market for over a year with no complaints in sight (at least that I could find).

For me, since this part is known to fail prematurely, it only makes sense to make this a serviceable part. The fact that you can replace this part without having to remove the driveshaft or drop the exhaust is a huge gain in my book. Even if the individual supports start to wear, they state that they will provide replacements. Once again, a huge improvement over the stock unit where Porsche will not just let you replace the bushing itself - which is absurd to replace a complete driveshaft, when the just the bushing should be replaced.

Last edited by Renaissance.Man; 04-30-2013 at 03:48 PM.